New types of dowel-based connectors, ones that are timber-to-timber and adhesive-free, could be a game changer for cross-laminated timber, given that “adhesives account for one-third of the CLT’s global warming potential, energy consumption, and nonrenewable fossil.”

That is according to research from the University of Gävle, which tested four types of adhesive-free connectors made of compressed wood that could be used in flooring systems as part of a four-point bending test.

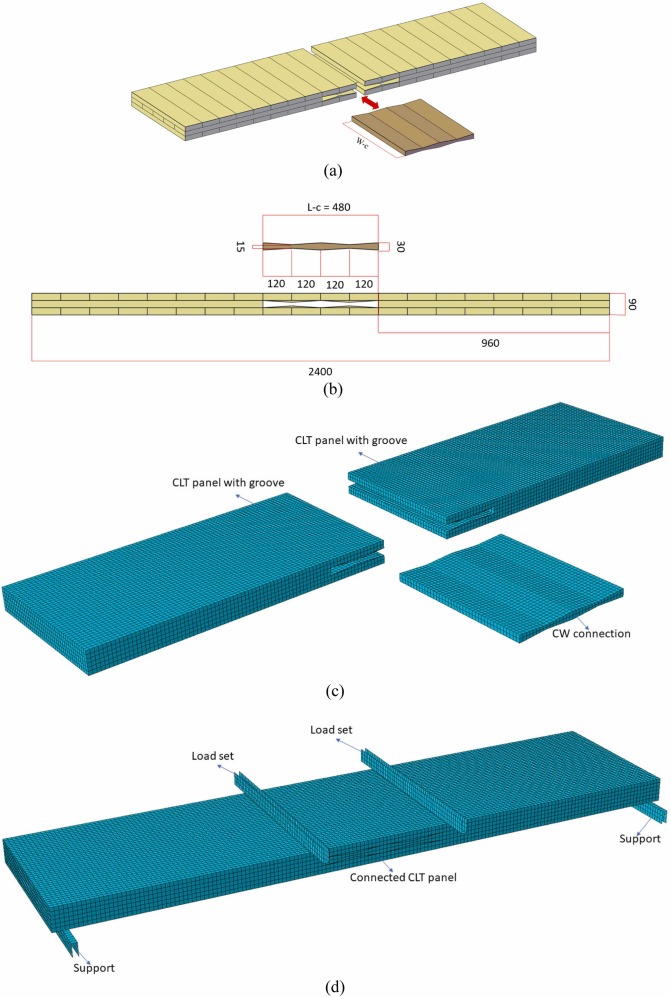

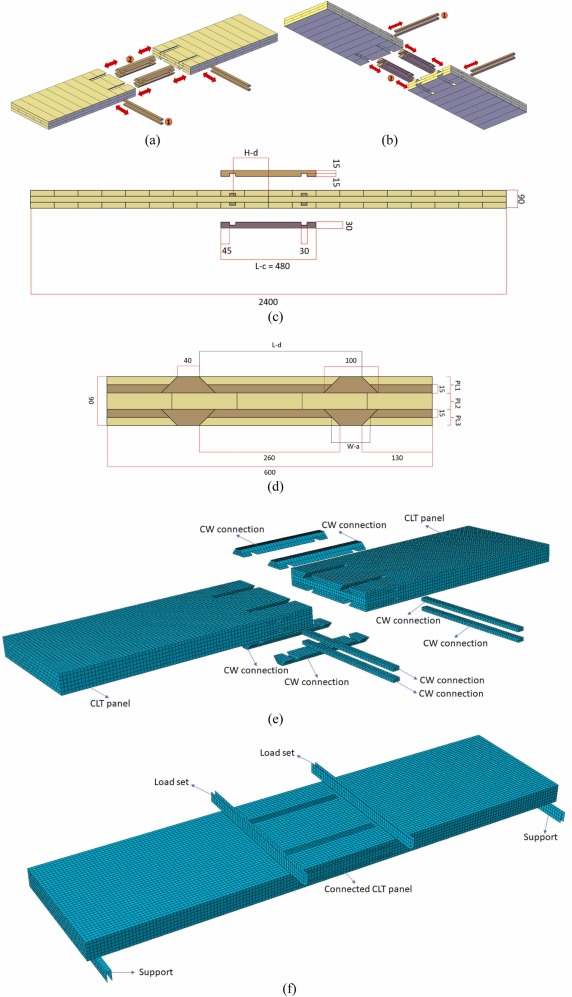

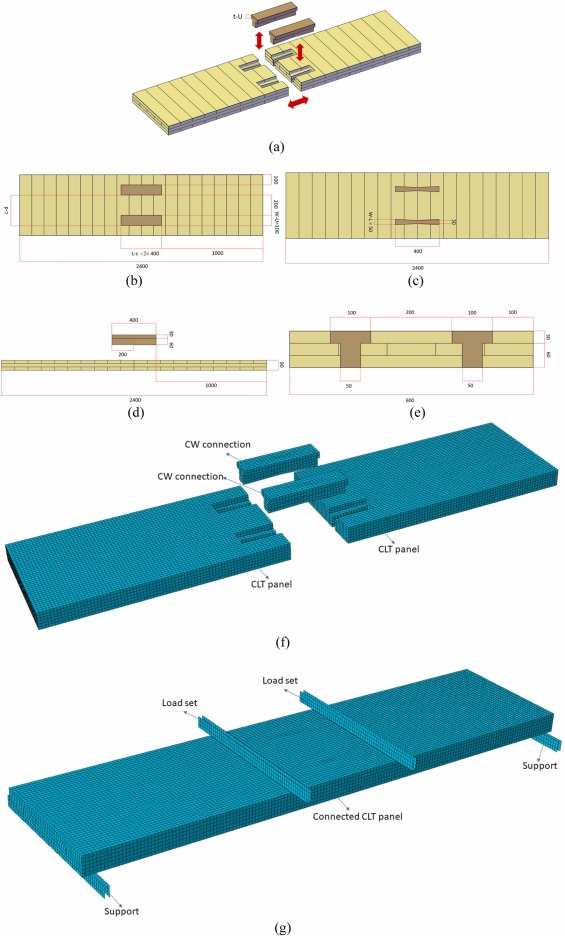

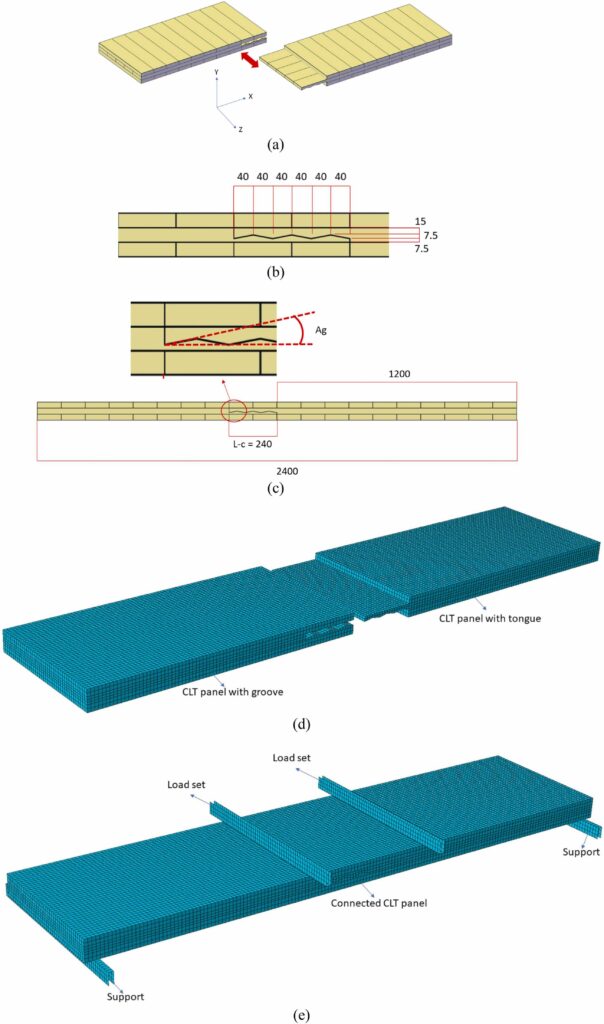

“Adhesive-free timber edge connections have the potential to be a viable alternative to high embodied energy steel connectors and synthetic adhesives in glued-laminated timber (GLT) construction,” according to lead author Dr Honghao Ren, who tested the belt connection (or B edge connection), T-shape edge connection (a T edge connection), a Grove-and-Tongue connector and a G-edge connection.

“The results showed that compressed wood connects have the potential to be an alternative to steel connectors and synthetic adhesives,” Dr Ren said, adding that “adhesive-free timber edge connection types focused on timber floor system presents a promising approach to improve the expandability and energy efficiency of timber panels.”

According to Dr Ren, “These results and conclusions serve as a basis for recommending further enhancements to timber connectors or developing new designs,” adding that “the modelling used in the research can be a reference for simulating mass timber panels with connections.”

Is DLT the Next Big Thing in Timber Construction?

In February, Wood Central revealed that the Australian government was supporting a new project looking to commercialise timber-to-timber connectors used in dowel-laminated timber (or DLT) systems— reportedly stronger, greener, and more affordable than cross-laminated timber—for use in low—and mid-rise construction.

It comes after Wood Central reported on a study published in the Journal of Building Engineering, Monotonic testing of single shear-plane CLT-to-CLT joint with hardwood dowels, which tested 154 different single shear-plane experimental tests using four different species used in DLT, including Douglas-fir, Grand-fir, Western-hemlock, and Spruce-Pine-fir, two hardwood dowel species, using two different dowel diameters.

“The objective is to evaluate the mechanical properties of the CLT-to-CLT joint, including yield and ultimate strength, serviceability and yielding stiffness, and ductility,” according to Aivars Vilguts, the lead author from Virginia Tech, who said the results could lead to a new approach for calculating hardwood dowels yielding strength and elastic stiffness – providing beyond doubt that a hardwood dowel offers higher strength stiffness compared to a wooden screw.

“Hardwood dowels have become one of the most popular fasteners for wood-to-wood joints,” he said, adding that “the most widely used hardwood dowels are Red Oak (in the US) and Yellow Birch,” Mr Vilguts said, adding that “experimental testing suggests that hardwood dowel joints have comparable or even superior performance than screws.”

- Honghao Ren, Alireza Bahrami, Mathias Cehlin, Marita Wallhagen, Proposing new adhesive-free timber edge connections for cross-laminated timber panels: A step toward sustainable construction, Case Studies in Construction Materials, Volume 20, 2024, e02975, ISSN 2214-5095, https://doi.org/10.1016/j.cscm.2024.e02975.