Wood scientists and professionals gathered at ‘The Conservatory’ in Cairns on Tuesday night to celebrate the introduction of itreat Timber’s new patented ‘green’ solvent preservative system.

Hosted by Scott Porter and KopCoat Australia, guests included delegates to the International Research Group on Wood Technology conference who were welcomed by itreat Timber managing director Gerry Gardiner.

Mr. Gardiner was instrumental in attracting and encouraging global wood protection company Kop-Coat Protection Products (KCPP) to share its patented technology with the Australian timber industry.

This continues at itreat Timber, based at Narangba, north of Brisbane, which is still significantly involved in the market development of this technology.

Now, some 12 years later, with several licensees in place and no known failures, Mr. Gardiner reflects on what this means to the timber Industry, the consumer – and most significantly, the environment.

“In an industry that already has outstanding credentials, this goes a step further in enhancing our value to the environment,” he said.

“The use of TRU-CORE® has significantly impacted in decarbonising some timber treatments.”

This is evident with Pacific Wood Tech in the US treating all veneers in its LVL products.

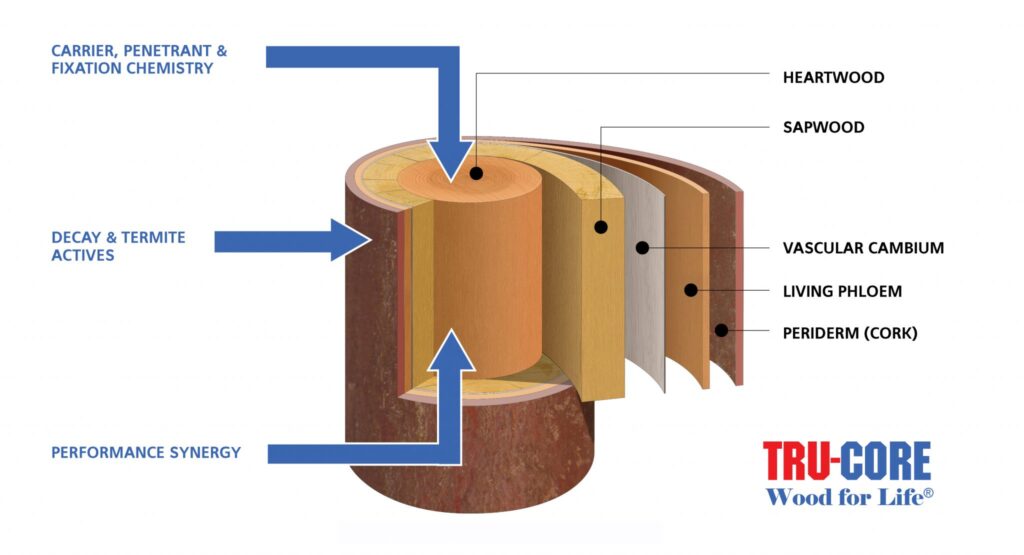

How it works

The process treats the finished product, not individual veneers, through a process where the active chemicals are released from the glue resin through the hot press application.

The system readily penetrates wood species and composites which do not normally allow for treatment by conventional methods for example, Light organic solvent preservatives (LOSP), copper chrome (CCA)

Looking back and gauging the volumes of TRU-CORE®-treated products compared to a mineral spirit hydrocarbon solvent-based process, Mr Gardiner believes there has been a swing to the water-based process by an estimated 25-30% – often utilising harvested rainwater.

“The transition from solvent-based carriers to water-based carriers is immediate – for every 500 cub m converted to TRU-CORE® from a light organic solvent preservative (LOSP), it represents an estimated saving equivalent of taking 130 cars off the road,” Mr. Gardiner said