The University of Kansas has unveiled plans for “Makers KUbe,” a six-storey mass timber building using a custom-built diagrid system. The new system combines glulam with dowels to create a Japanese joinery technique that eliminates the need for steel fasteners and plates.

Designed by Bjarke Ingels Group (BIG), who, in close collaboration with executive architect BNIM, the Kansas School of Architecture of Design and structural engineers StructureCraft, the new 15,000-square-metre Makers KUbe will eventually consolidate the school’s architecture, design, and robotics programmes under the one roof.

“Our design for the consolidated design studios (at KU) seeks to deploy all aspects of the profession in three distinct interventions: preservation, adaptation and new construction,” according to BIG founder Bjarke Ingels, who earlier this month revealed plans for Bhutan’s new megacity made from mass timber, bamboo and stone. “The Makers’ KUbe will showcase timber tectonics, traditional joinery, robotic manufacturing, and sustainable materials.”

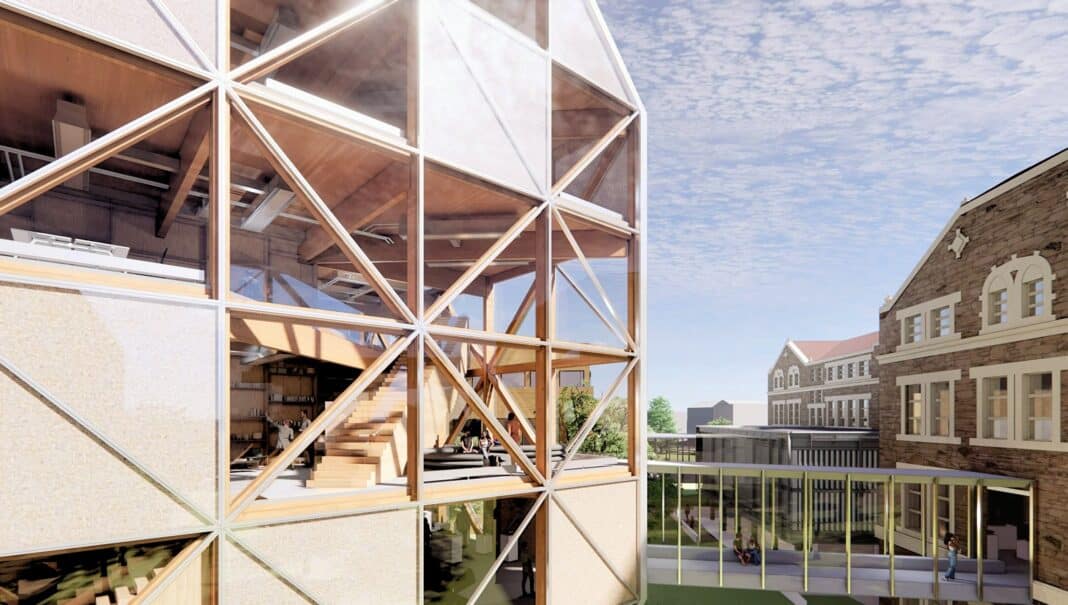

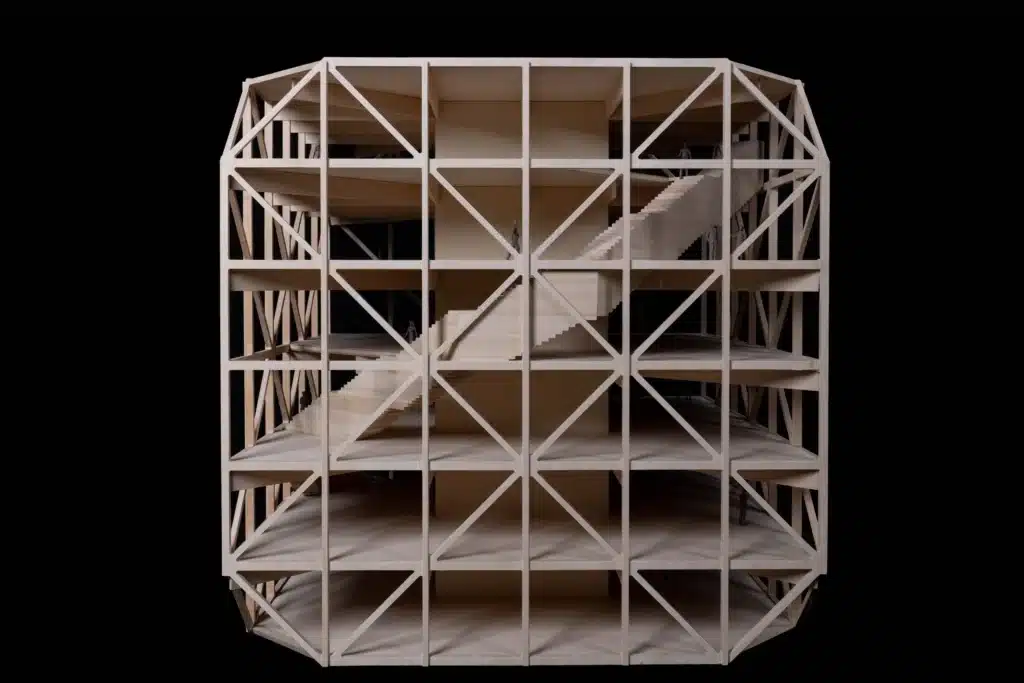

The new building design will install bridges on the second level to connect the campus to surrounding buildings on either side of the cube. In addition, it will have chamfered edges on all corners, creating entrance canopies on the ground floor and terraces on the top floor.

The facade will be wholly clad in glass, with a crisscross of panels opening from the inside and outside, showing the building’s insulation like “shadowboxes.”

“The timber bones of the building are exposed by stripping away all applied finishes – elevating a structure to expression,” according to Mr Ingels, who said that the building will “serve as a living curriculum, revealing all the function, technology and structure as tangible elements for students to appreciate and critique.”

Inside, the building will feature exposed wood beams and panels, with a staircase that circles the core. According to Mr Ingels, the core was minimised by using a self-supporting, fire-resistant egress to expand the floor plates – with the diagonal mass timber columns combining to make up the diagrid structure that helps with load-bearing.

“A fire-resistant egress feature staircase spirals up the building, encouraging spontaneous moments of creative interaction and maximising available floor space,” said the studio, adding, “All interior materials are recyclable.”

The new design comes after the NZ-based Te Whare Nui o Tuteata, or Scion Innovation Hub, was crowned the world’s most beautiful, innovative and iconic building, thanks to its mass timber diagrid system – which helps to create mass timber buildings to geometrically stiffened forms to help in earthquake prone environments.

- To learn more about the Scion Innovation Hub and why it has secured more than 20 international design awards, visit Wood Central’s special feature.