Glass timber panels (or GTPs) could hold the key to cracking the $40 billion medical industry with a new veneer-based product perfect for furniture, floors, and work surfaces in hospitals, aged care facilities, healthcare facilities, as well as in restaurants, shopping centres, and public transport.

That is according to a new paper published by Sagar Vanapalli and Stefan Reisch, two German researchers, who have tested a new type of hybrid wood that is impermeable to water, easy to clean and resistant to disinfection and chemicals used.

It is part of a suite of research produced by the German Federal Ministry for Economic Affairs and Climate Action, with the researchers confirming that:

“Glass timber panels (GTP) combine the visual effect of noble and high-quality wood materials while meeting the hygiene requirements for the health and welfare sector,” before adding that the new research “describes the fabrication requirements and techniques of GTP.”

“GTP offers a high-quality wooden surface that meets the same hygiene standards as ceramic, metal, or plastic,” allowing “greater design flexibility and a warmer aesthetic while ensuring that hygiene standards are met.”

And whilst past attempts have failed to laminate raw wood to glass – “due to its uneven surface, resulting in delamination,” a plain veneer surface “provides a smoother and flatter surface for lamination.”

“While veneer surfaces can still have some roughness, a thicker EVA foil is used to compensate for grooves or imperfections. The foil melts and fills these areas during lamination, resulting in a solid and durable bond between the glass and wood.”

The result is a product with “a high-quality protective layer that can withstand wear and tear while enhancing the wood’s visual appeal.”

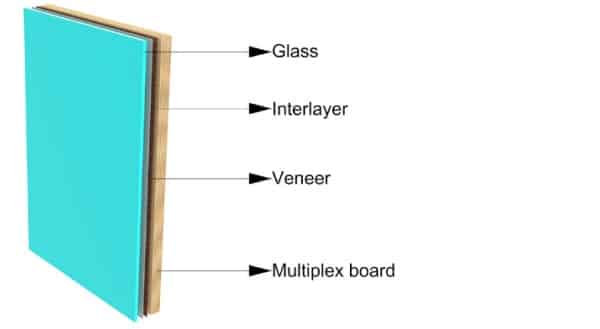

According to the researchers, the new product combines multiplex board and veneer with an interlayer and a laminated piece of glass. With the glass “using a similar lamination process safety glasses.”

Veneers made from oak, walnut, elm, core ash, teak, and larch were tested for durability, with larch the only species to show cracking under intense testing. In addition, a new type of interlayer, which only laminated the veneer and not the multiplex, was used, which, for the first time, controlled warping against intense cleaning agents.

“The initial phase of GTP development has yielded promising results, as evidenced by the successful adaptation of the safety glass lamination process for glass and timber without compromising the wood’s aesthetic values,” the researchers said. Moreover, the durability tests confirmed that the lamination could endure continuous exposure to harsh cleaning agents.”

As for the next steps, “GTP development will focus on testing and evaluating the durability of 2D and 3D lamination” and use thinner pieces of laminated glass to produce lighter and more commercial panels.