We love takeout. It’s convenient, economical, eminently practical and also quite delicious. One of the things that keeps takeout accessible is something that we tend to ignore – the packaging. Disposable packaging is an essential part of the food sector and is currently the only widespread solution for transporting food items and many other goods. The convenience of single-use packaging is, in fact, an essential part of what makes the food industry viable.

This becomes a problem when we consider that hundreds of millions of containers and packages are thrown away daily worldwide. While plastics are the most common materials used in packaging worldwide, there is a growing movement towards adopting more sustainable packaging to combat the growing plastic pollution problem.

While transitioning away from single-use plastics is crucial, environmentally conscious manufacturers face the challenge of replacing them with sustainable alternatives. Fibre-based paperboard products, like cartons replacing plastic bottles in beverage packaging, offer a promising solution. However, certain types of packaging still present hurdles—for instance, the ubiquitous six-pack of cans held together with plastic rings. Here, durable alternatives crafted from biodegradable polymers, such as PLA, PHA, PBAT, and starch, are now available.

However, simply opting for biodegradable materials isn’t enough. The increased demand strains Earth’s forests, which provide the raw materials for this new direction. The reality is that to be truly sustainable, food businesses must answer consumer demand for eco-friendly packaging, but not at the expense of our crucial allies in the fight against climate change: forests.

The case for certified sustainable fibre-based packaging

Fibre-based packaging (FBP) is made from natural fibres from growing plants such as trees, wheat, and sugarcane. These fibres can be sustainably produced without any direct reliance on non-renewable feedstocks. FBP can also be easily recycled multiple times into new products. Because they are naturally biodegradable, they do not represent any long-term environmental hazard.

According to the Smithers report on ‘The Future of Fibre-based Packaging to 2027’, fibre-based packaging is growing fast, with the market size projected to be up from $425.4 billion in 2022 to $503.4 billion by 2027. However, for fibre-based packaging to be sustainable, the raw material it is produced from needs to be sourced responsibly.

This means ensuring the feedstock comes from carefully managed forests and plantations that maintain their biodiversity, productivity, regeneration capacity, vitality and ecological, economic and social functions. Sustainable forestry practices like selective logging, controlled replanting, and responsible waste management are crucial to maintaining and regenerating our forests for the long term.

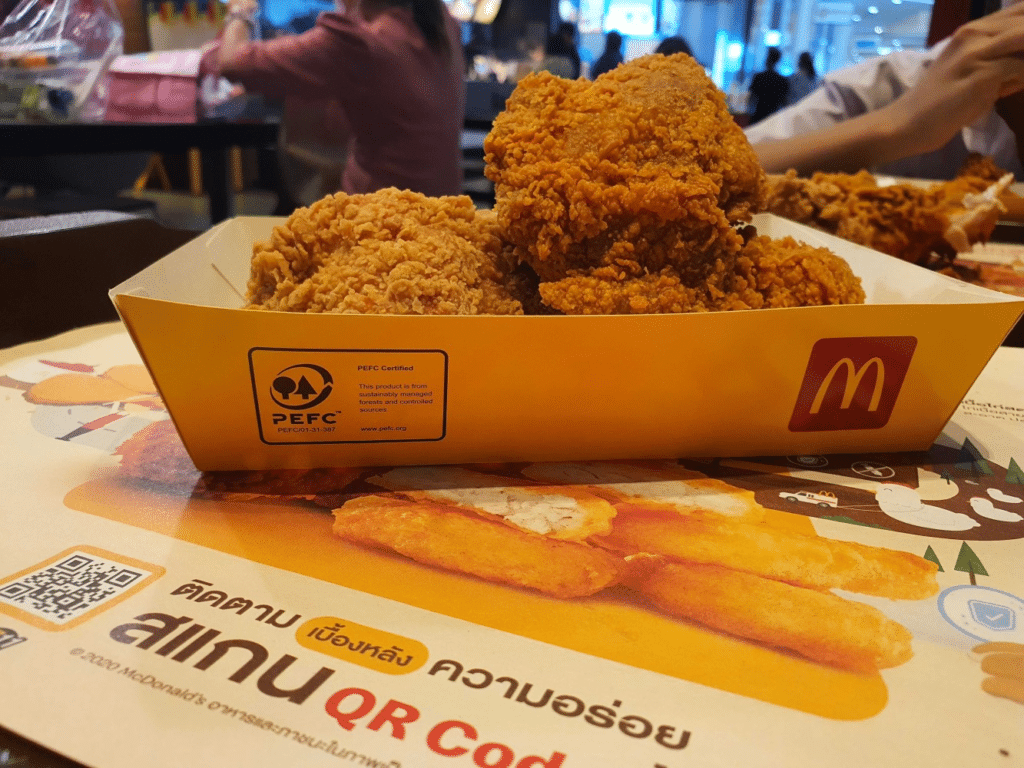

While the Smithers report indicates a strong trend towards the adoption of ‘rigorous traceability and certification programmes’, only about 13% of the world’s forests are certified. Global non-profit organisation PEFC International empowers forest owners worldwide to showcase sustainable management practices, endorsing national systems through a recognized multi-stakeholder process. With 71% of certified forests under its standard, global recognition by PEFC fosters trust and assurance for consumers about the sustainability of products bearing their logo.

National forest certification systems seeking PEFC endorsement must undergo a robust multi-stakeholder process, ensuring forest owners globally can showcase their sustainable management practices. This opens doors to new markets and opportunities for responsible forest owners, sustainable packaging producers, and retailers, providing them with a competitive edge in a world increasingly focused on ethical sourcing. PEFC certification promotes transparency and ethical trade, ensuring fibre products don’t contribute to deforestation, a significant driver of climate change. By choosing PEFC-certified options, consumers become active participants in protecting our forests and their invaluable role in mitigating climate change.

Beyond climate action, embracing certified sustainable packaging is a strategic move for your brand. Today’s consumers are increasingly discerning, with 64% expecting more from retailers and brands regarding sustainability. Highlighting responsibly sourced packaging materials through recognised certifications like PEFC sets you apart, attracting eco-conscious customers and building brand loyalty. There’s a clear advantage to highlighting that packaging material is sourced responsibly.

How businesses are using forest standards to combat climate change

With the increasing demand for sustainable packaging solutions, more producers of fibre-based packaging are stepping up to ensure sustainability promises are carried through from the source. This means they can pass on the assurance that their products are truly sustainable and stand up to the growing customer scrutiny, making them a supplier of choice for retailers that want to verify sustainable packaging material.

Suzano, a Brazilian paper and pulp producer, states their methods are “a global reference for the development of sustainable and innovative solutions from renewable sources and is committed to renewing life from the tree. We incorporate the environmental, social and economic dimensions into its forest management basic guidelines”. As part of their business operations, Suzano claims:

- To seek technological innovations and to support research to apply the best forestry techniques in its forest production units.

- To contribute to the professional development of direct and indirect collaborators.

- To implement the Forest Production Plan based on environmental aspects, such as landscape and micro basins management, monitoring of fauna, maintenance of biodiversity corridors, and compliance with the applicable federal, state and city legislation, as well as international agreements of which Brazil is signatory.

- To contribute to the maintenance or improvement of communities surrounding the forest management units through open dialogue channels, participative follow-up of social indicators, sharing relevant information and promoting recreation areas or environmental education.

Leading producer of pulp and paper products APRIL Asia Pacific Resources International Limited (APRIL) Group is reported to sustainably manage over 740,000 hectares of plantation forestry concessions that are PEFC certified. In 2022, APRIL Group expanded the area certified under PEFC to include its Restorasi Ekosistem Riau (RER) Ekosistem Riau forest restoration program to cover 150,000+ hectares.

Instead of risking encroachment on precious conservation forests, APRIL Group’s ‘ring plantation’ method surrounds them with productive acacia plantations. Born from the need to combat unmanaged land degradation, ring plantations blend sustainable forestry, conservation, and local development, providing a sustainable source of raw materials for more environmentally sustainable packaging solutions.

Rohit Ghosh, Commercial Head, Paperboard, of the APRIL Group, sums up the imperative for incorporating and passing on the claim of sustainability down the value chain:

“Internationally recognised and credible certification is a key part of our approach to ensuring that our forest plantations are managed in line with best forestry practices management. Our PEFC International certification helps us to provide assurances to our stakeholders that our products and our processes, across our operations, meet credible international standards.”

Letchumi Achanah, Head of Stakeholder Engagement and Advocacy at Asia Pulp & Paper (APP), commented: “We firmly believe in nurturing the planet through responsible business practices, ensuring a future where nature thrives. Our commitment to sustainability starts from the ground with supply chain traceability and sustainable forest management and extends to innovative solutions like Foopak, our plastic-free paper cups and trays.

We’re proud that all our products bear the PEFC International certification, a testament to our dedication to responsible sourcing and environmental preservation.

At Asia Pulp & Paper, sustainability goes beyond words; it’s action-driven through various initiatives to ensure we meet our sustainability commitments and apply the same principles to our suppliers.”

Looking down the supply chain, convenience store chain Circle K, with 2000 stores across Europe, has been using PEFC-certified paper in its food packing as part of its sustainability goals. Vibeke Veiseth, Senior Concept Development at Circle K Europe, said, “Food is a crucial part of our business, and with food comes packaging. As we serve our great food in all European markets, this means we use large volumes of paper within our food packaging. Reducing plastic in our pastry bags is one part of our sustainability journey. The bags are only made of PEFC-certified paper.”

There’s no doubt that many more big and small brands worldwide are incorporating certified sustainable material into their packaging solutions.

A sustainable value chain provides advantages for every participant in it. By incorporating certification into the sourcing of materials and formulating sustainability goals, the packaging industry can be well on its way to doing its part for climate action.