Australia’s largest hardwood timber manufacturer is investing in new robotic CNC technology, streamlining the production of engineered floors in the latest push by Australian manufacturers to deliver the next generation of mass timber products.

On Friday, Australian Sustainable Hardwoods (or ASH) started commissioning a new ROBOT-Max machine that will use a fully automated system assembly to feed, lift and dispose of waste – which could, once installed, drive a circular economy for hardwood forest products.

It is the latest move by ASH, which is now rising from the ashes following the decision by the Victorian Government to end native forest harvesting with its MASSLAM business now crucial to delivering on Managing Director Vince Hurley’s quest to diversify resources, create higher value products and continue to innovate.

Last year, Wood Central’s Senior Editor spoke to General Manager Dave Gover, who exclusively revealed that ASH is reinvesting in new equipment to boost its MASSLAM capacity.

“Responsible sawmilling is about finding the right market for 100% of the fibre processed,” he said, adding that “we’re installing (our third ) mass timber robotic CNC, which will further increase current capacity and give us the ability to take on extra work in future years,” according to Mr Gover, who spent five years as CEO of the Engineered Wood Products Association of Australasia.

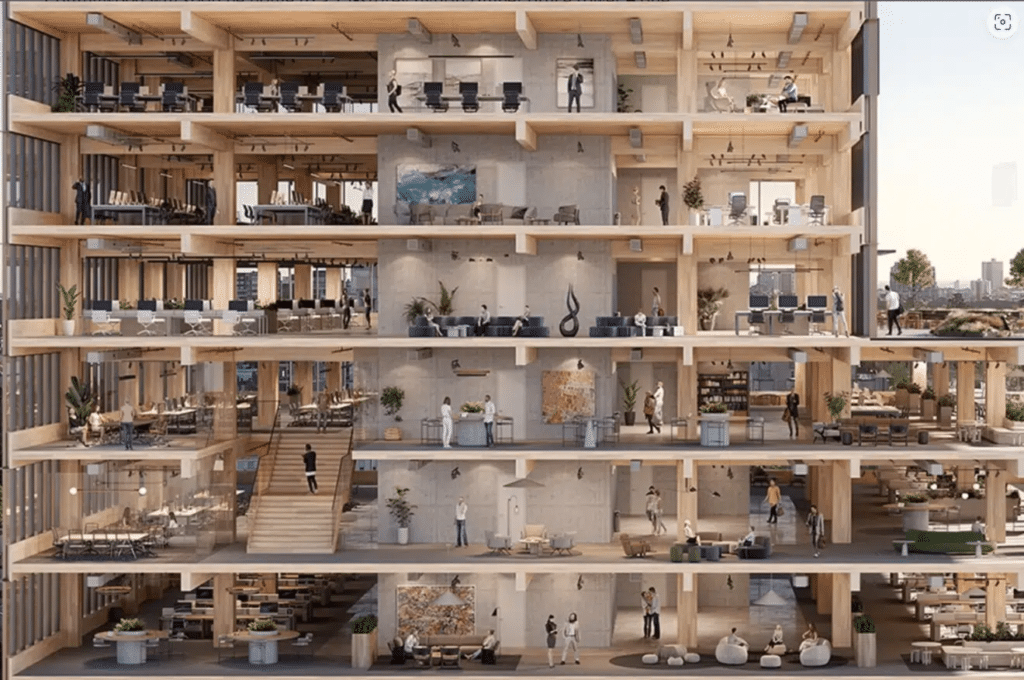

MASSLAM is a glue-laminated flooring system used extensively in the T3 Collingwood – the first mass timber building delivered as part of the Australian Government’s Clean Energy Finance Corporation’s timber incentive program, with the product already used in driving 5-start and 6-star timber buildings across Australia.

In addition, the new machines will help in producing ASH’s new Advanced Timber Composite product (or ATC), a new flooring system that not only expresses timber soffit through DtS fire solutions, “but also has high acoustic performance, longer spans, and, most significantly, improves onsite construction-phase moisture challenges.”

ATC can run between the beams, satisfying acoustic vibration and fire solutions in one go. Mr Hurley claims that the product could be vital to addressing Australia’s housing crisis, adding that it is “very cost-effective, and unlike other solutions, you can see the timber.”

Wood Central understands that the new machines, which Hundegger Australasia supplies, will be installed over the next few weeks and, once complete, will be the first of its kind in Australia.