The world’s largest supplier connectors supplier is developing new products to drive the next generation of offsite manufacturing and mass timber construction.

Last week, Strong-Tie launched MASOZ™, a new mudsill anchor that eliminates the need for construction crews to drill and set anchors after wall panels are in place. It also eliminates the need for blocking and connectors over sheathing.

“As more builders switch from stick-built framing to offsite fabrication, traditional mudsill anchors for sheathed wall panels are proving too labour intensive for the application,” according to Randy Daudet, Strong-Tie’s Product Manager for Mass Timber/Offsite Products, who added that the new connectors “allows panels to be installed without the hassle of aligning sill plate holes with protruding anchor bolts.”

Strong-Tie, which will present at the International Mass Timber Conference in Portland, is pivotal in driving mass timber adoption across the US and worldwide – which could grow 25-fold over the next 50 years in the US.

Yesterday, 15 timber stakeholders from the Asia-Pacific region visited Strong-Tie’s headquarters in Stockton, California, before touring its purpose-built Tyrell Gilb Research Lab.

On tour are nine representatives from Taiwan, two from Japan and South Korea, and single representatives from Mainland China and Australia.

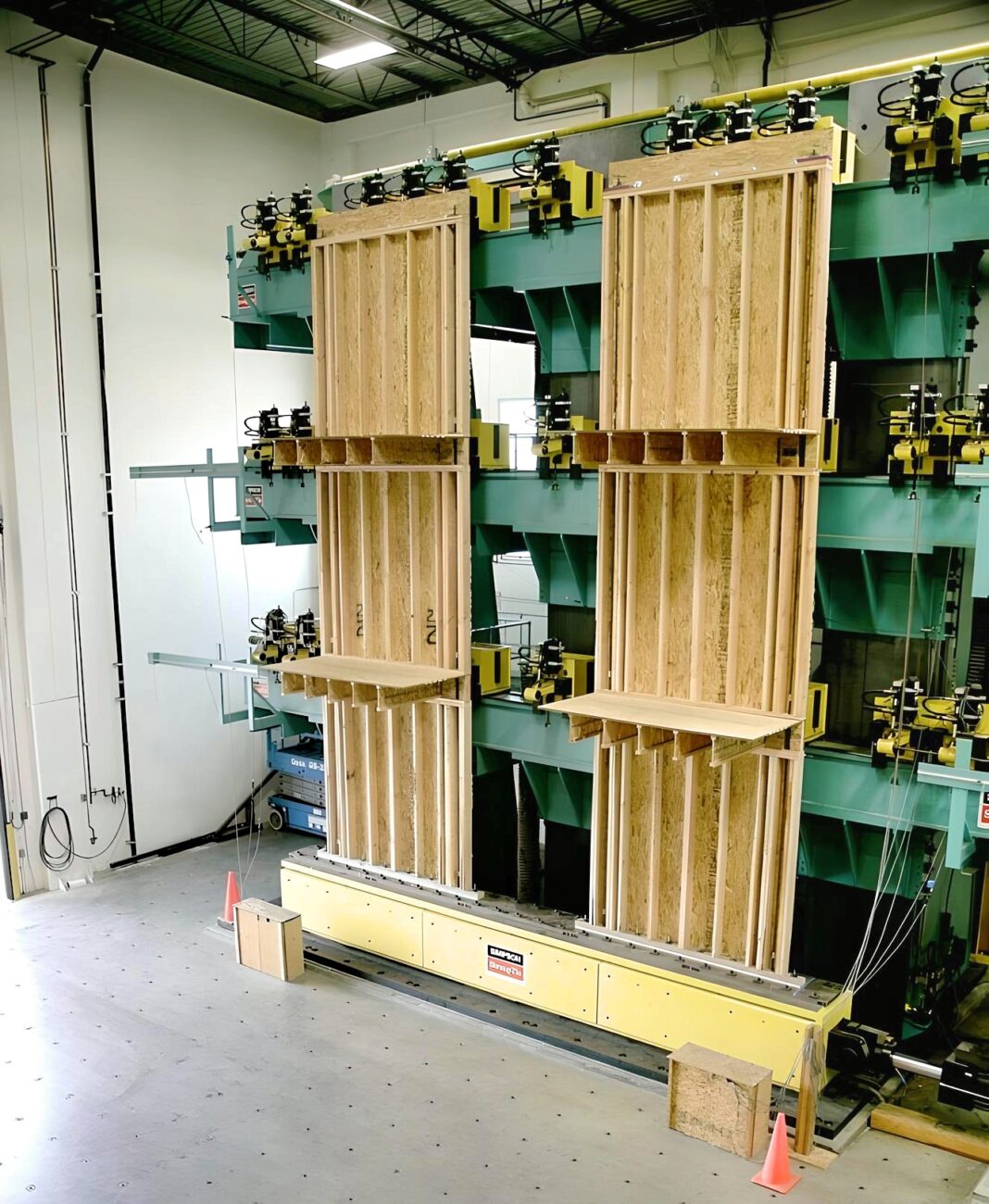

“We were fortunate to visit the Strong-Tie factory and look at how they make framing brackets,” according to Andrew Dunn, the Australian representative on tour, who added that the group also visited the “one-of-a-kind uniaxial shake table, which can test full-scale three-storey wall assemblies.”

“Strong-Tie was involved in the “Shake Test” last year, and here in Stockton, California, it can test portions of a building (like walls) rather than the entire structure itself.”

“Remarkably, Strong-Tie uses ground motion recordings from real-life seismic events, with the shake table testing specimens with an inertial weight of up to 60,000 lbs,” Mr Dunn said, “which use some of the largest ground motions recorded to date.”

The centrepiece of the Tyrell Gilb Research Lab, so named in memory of Tyrell (Tye) Gilb, who led Strong-Tie’s R&D for 35 years, said the shake table is in the middle of the 25,000-square-foot facility and is secured against a 10,000-square foot reinforced “Strong-Floor.”

“The floor is three feet thick and designed to withstand 300,000 pounds in load,” Mr Dunn said, with over 10 million tons of reinforced concrete in the walls and core.

“Why so much concrete? For two reasons,” he said: one, greater flexibility when testing heavy loads, and second, the actuators need a significant reaction time when testing specimens through earthquake simulation.

“If the reaction mass of the lab floor was not so large, cyclic tests could transmit vibrations through the rest of the building.”

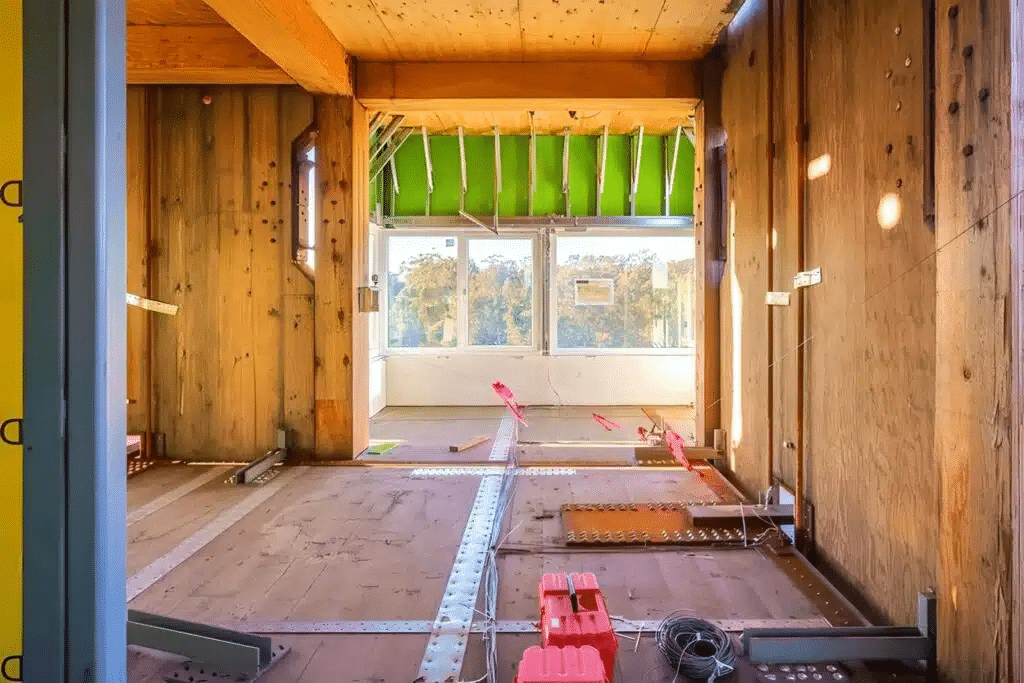

As part of the TallWood research project, Strong-Tie R&D was instrumental in testing a 10-storey cross-laminated timber building 100 times as part of the world’s largest seismic test.

The result was a new type of rocking wall system, which, according to lead researcher Professor Shiling Pei, could soon be added to building codes in the United States, Japan, and globally via the International Building Code.

The rocking walls are self-centred to prevent significant damage during a quake. “Each 3-metre-wide panel spans the tower’s height and is anchored to the world’s largest outdoor shake table via Strrong-Tie’s steel rods,” Professor Pei said, adding that “rods control the motion of the walls, allow them to lift on one edge and compress on the other.”

“When the shaking stops, the rods bring the wall’s edge back to being flush with the shake table — equivalent to the foundation. Thus, the building returns to its original vertical position.”

Mr Dunn and the Asia-Pacific delegation will now travel to Portland, Oregan, courtesy of US-based host APA, The Engineered Wood Association, where they will attend the International Mass Timber Conference later today.

- Wood Central will have exclusive updates from the delegation and the International Mass Timber Conference as it happens.