Bamboo has the potential to be as dominant as concrete and steel, with its strength and availability making it a compelling solution for low-carbon buildings.

That is according to Chris Matthews, a structural engineer with Atelier One, who spoke about the potential of bamboo as a low-carbon substitute for green steel in an interview with Dezeen.

Mr Matthews, who is a specialist in structural bamboo, believes the material has the potential to be used in a similar way to cross-laminated timber (CLT).

Addressing bamboo’s disadvantages, specifically its susceptibility to insect and fungal attacks, he said the key is to ensure that the material is treated to remove starch and that the material is not directly exposed to the sun, water or ground.

“The issue has been that [bamboo is] prone to fungal and insect attacks,” he said. “You’ve now got a material that not only has this amazing speed and strength, but it’s also able to have longevity.”

He claims scrimber, cross-laminated timber bamboo (CLTB), and even radial laminated bamboo (his favourite) are among new products that can match timber for strength in specific applications.

Investment in bamboo is booming, with investments in Brazil, Malaysia and, most recently, China adding to the momentum behind the material.

Last month, Wood Central reported that researchers from Bristol University have invented “bamboo safe screws” whilst China is leading research to integrate locally produced bamboo into cross-laminated bamboo and timber (CLBT) engineered panels.

In addition to research, bamboo is already being used in various award-winning projects, including Nayara Bocas del Toro in Panama and the UNESCO Prix-Versailles award-winning Ulaman in Bali.

With the global demand for timber expected to quadruple over the next 30 years, bamboo is a potential regional solution in countries lacking forest resources.

In April, Wood Central reported that 80% of the world’s bamboo species are found in Asia – in regions not conducive to softwood plantations.

“In general, the idea of bio-based materials where we are capturing carbon and locking it up in a building, that has to be the way forward,” Mr Matthews said in the Dezeen interview.

However, one of the drawbacks to the material is its heavy reliance on water. In April, Wood Central spoke to an insider connected to Asia Pacific forestry who said the key is to be strategic with planting.

“It is highly effective as an agricultural crop in areas of natural high waterfalls; farming bamboo in areas heavily reliant on irrigation can harm the environment,” they said.

Nonetheless, if planted correctly, many international architects and sustainability professionals are pushing for the material to be used in areas that are not conducive to softwood timber species.

That includes mass timber pioneer Michael Green, who, earlier this year, in the keynote address at the International Mass Timber Conference in Portland, discussed the value of bamboo in meeting demand for timber in countries that either lack forest or have severely threatened forests.

“Huge parts of the world either don’t have forests or have super-threatened forests, and wooden buildings are not a good solution to the stock from sustainable forestry,” according to Mr Green.

“So, the work we’re doing now is focused on grasses, bamboo, other plants, and trees.”

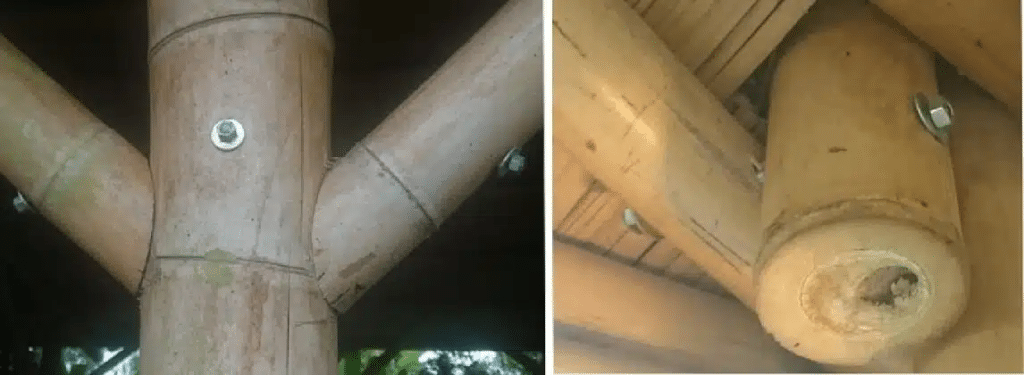

Meanwhile, Atelier One is now looking to 3D-printed connections to link bamboo together and improve its strength.

“So you’ve got this solid material, and now what we’re trying to play with is how you get the full strength out of it,” Mr Matthews said. “It’s all about the connections.”

“We’ve started playing with 3D-printed connectors to link pieces of bamboo and get a longer fabric. Once you start playing with the shapes, there’s no end to the possibilities.”

According to Mr Matthews, Radlam – a type of radial laminated bamboo is Atelier One’s favourite, “as it is processed in a way that retains all the layers of a bamboo culm, reducing waste and maximising strength.”

“We like this because you get the whole culm, so the whole thickness of the bamboo – you’re not wasting material as you process it,” he said.

“And also, by not passing off the outer skin, you’re getting the full strength,” he continued. “It’s three times stronger than standard timber, so the properties are amazing.”