One of Australia’s largest energy distribution network providers, responsible for supplying power to 890,000 dwellings, is embracing fibreglass composites to supply the next generation of power lines. By 2030, it will replace all traditional hardwood-based utility poles with highly durable composites able to withstand high wind loads and impacts.

Last month, Wood Central reported that Essential Energy, which supplies power to NSW and Southern Queensland residents, will replace 11,200 poles every year (including 2,200 in bushfire-prone areas).

As per a submission to the Australian Energy Regulator (AER), the state-owned Essential Energy said the switch was not only due to long-term uncertainty over hardwood supply in State Forests “but also to boost resilience in bushfire-prone areas and reduce environmental impact on power line maintenance.”

What are fibreglass poles? How are they different from steel, concrete and wood?

As it stands, the utility pole market is experiencing massive growth as older networks reach end of their life across the Western World. Globally, more than 20 million utility poles are replaced every year, with research showing that 50% of replacement utility poles are made from wood, 37% from steel, 10% from concrete, and 3% from composites (including fibreglass).

Composite, fibre-reinforced polymer (FRP), or fibreglass utility poles were first installed in Hawaii in the early 1960s due to the high humidity and high wind environment: “As experienced in Hawaii, the main advantages are the corrosion resistance of the material, low maintenance requirements, immunity to termites and pest infestation”, according to the Assessment of Commercial Composite Power Pole Performance, a 2021 report looking at the viability of fibreglass poles.

Although not fireproof, with just one coat of fire-retardant, the poles are fully fire-resistant, making them “attractive to service utilities containing brushy terrain, forests, or combination of both,” the report said.

However, despite advantages, “composite poles are not widely used for high voltage apply high-voltage (over 230kV), possibly due to the greater amount of deflection under load compared to steel and concrete, and also due to the lack of knowledge of how the material performs in a high electric field environment.”

What is the fibreglass impact on the Environment?

According to Polesaver, the UK-based innovator behind the world’s first dual-layer ground-line barrier sleeve, which is used in 35 countries and sold in Home Depot and other “big shed” stores worldwide, composite pole manufacturing “is by far the worst when we look at the water used in production, which is considerably higher than any other material.”

“Composite poles use an estimated 1,248 gallons of water per pole,” Polesvaer said, adding that wooden poles, such as Pentachlorophenol treated poles, “use only 46 gallons of water per pole and by far the lowest amount of fossil fuels of any material.”

In May, Wood Central spoke to Richard George, the CEO of Polesaver, who said that wooden poles “are still (by far) the most environmentally friendly carbon product.

“It is important to buy wood “but make it last longer” and use innovative solutions, including sleeves, fabric or both, “to reduce pressure on the forest green.”

Richard George, the CEO of Polesaver who spoke exclusively to Wood Central earlier this year.

That’s because all pole types produce anthropogenic greenhouse gases and ecotoxicity air emissions during production.

But, the worst effect of utility pole types is the production of CO2 over the entire lifespan.

“To put this into perspective, AquaAe Ter Inc. released a report stating that the CO2 output from a single concrete pole is 1460kg, steel is 784kg, and composite is 867kg,” Polesaver said, with wooden poles producing minimal impacts compared to all other pole materials.

“(Polesaver’s) research indicates that wooden poles absorb CO2 from the atmosphere during their estimated 40-year life cycle as trees before harvesting. Roughly half the dry fibrous mass of a wooden pole is made of carbon, which strikes an environmental balance by outweighing the CO2 generated from processing. AquaAe Ter states that a wooden pole absorbs 320kg of CO2.”

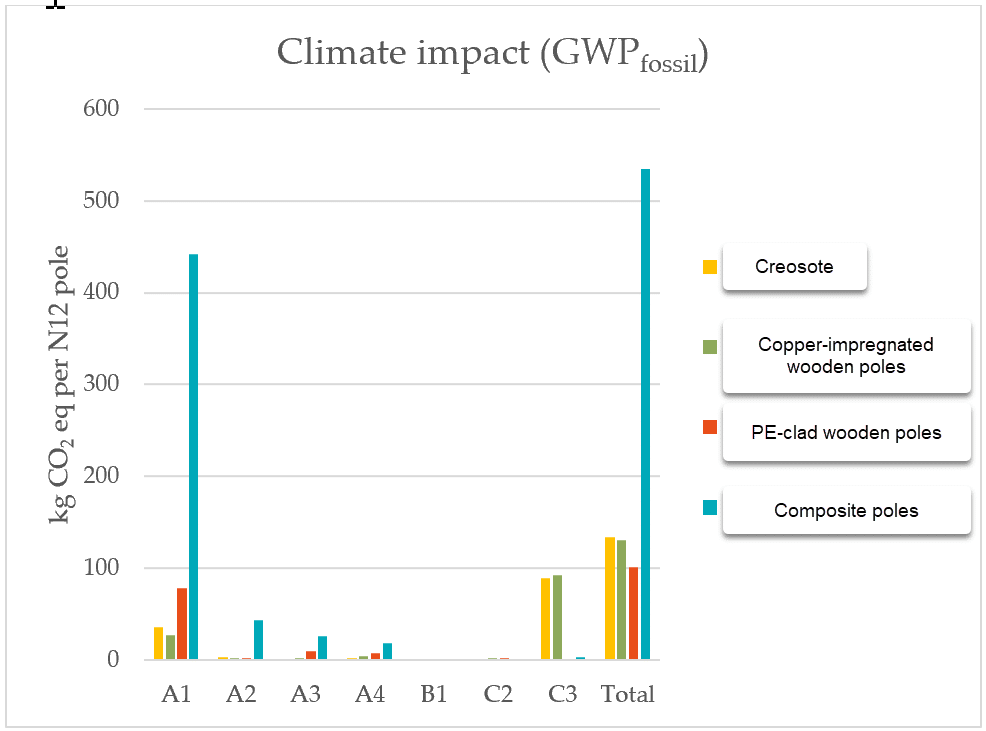

This is backed up by a Swedish LCA of different utility poles, which showed that wood-based poles were approximately 5 times better for climate impact than composite poles.

Co-financed by the Foundation for IVL Swedish Environmental Research Institute (SIVL) and Energiforsk (Swedish Energy Research Centre), and carried out by IVL Swedish Environmental Research Institute, it found that composite poles were roughly between steel and concrete in terms of climate impact.

And then there is disposal…

Concrete poles have non-recyclable/non-reusable properties and are disposed of in landfills. Steel poles, by contrast, are usually recycled, and composite poles are burned for energy recovery or disposed of at landfill sites. Generally, wooden poles are burnt, re-purposed or sent to landfill.

“Our research suggests that wooden poles have the lowest environmental impact at disposal.”

Polesaver, who has developed the world’s first dual-layer ground-line barrier sleeve for timber power poles

Although “burning composite poles is an excellent source of energy production, the facilities to do this might only sometimes exist.”

“If it is more cost-effective, composite poles end up at landfill sites.”

The cost to swap: Fibreglass switch to hit Aussie wallets…

According to Essential Energy, the direct result of this material switch will cost households $39.00 extra per year and businesses $89.00 per year – after Wood Central reported that a switch from hardwood to concrete or steel would cost the state government $25m in costs.

In March, Wood Central spoke to an expert connected to Australia’s energy distribution network who warned that the long-term supply of hardwood power poles from NSW and Queensland would be threatened if native forest harvesting ceased in both jurisdictions.

“And that’s just new line establishment,” they said, adding that with the ongoing wild weather across the east coast of the country (which will only get worse thanks to climate change), “maintenance of existing infrastructure during storm activity is highly problematic.”

According to the Australian Energy Regulator’s 2021 report, “Electricity network charges make up 40- 50% of a residential customer energy bill in 2020-21.” The report also adds that “Distribution networks account for the majority of costs (73-78 %), with transmission network costs (up to 21%) and metering costs making up the balance.”

“If the supply of timber poles stopped, in line with the shutdown of the native hardwood industry, new poles would be needed, and the replacement would be steel, fibreglass, or concrete,” the expert said.

As it stands, “timber poles have a price advantage over alternate materials, as well as advantages in flexibility in use, natural insulation, compatibility with the existing infrastructure, carbon cycling, and sustainability over other materials like concrete, steel, and fibreglass.”

- Please Note: Wood Central is a neutral platform and will not take an editorial stance over Australia’s native harvesting (or logging) debate. However, in matters of public interest, it will post opinion articles and invite subject matter experts from all sides to provide contributors, who will be fact-checked before publication.