- When Arch Chemicals purchased the 51% share of its Koppers Arch joint venture it took the Australasian wood protection business full circle, inheriting the legacy of the Hickson organisation, which more than half a century ago dominated the industry as a single entity supplier of timber preservatives, reported Jim Bowden in August 2007.

The development means that Koppers Arch, which was established as a joint venture in 1989, will come under the full ownership and control of Arch Chemicals, a global biocides company with annual sales of about US $1.4 billion.

The general manager of Koppers Arch in Australia and New Zealand Graeme Rees said the Arch announcement was a positive development for the group and its customers.

“While we have enjoyed a successful relationship with our joint venture shareholders over the past 18 years, the new arrangements will give us even greater access to the technology and strengths that have made Arch Chemicals a leading international specialty chemical and biocides company,” Rees said.

“For our customers, it is a case of business as usual as we will continue to help them grow their businesses by providing world-class wood protection products and services.

“But in the longer term, we see exciting potential for introducing new technologies to our markets and greatly enhancing international relationships and networks in the wood protection industry.”

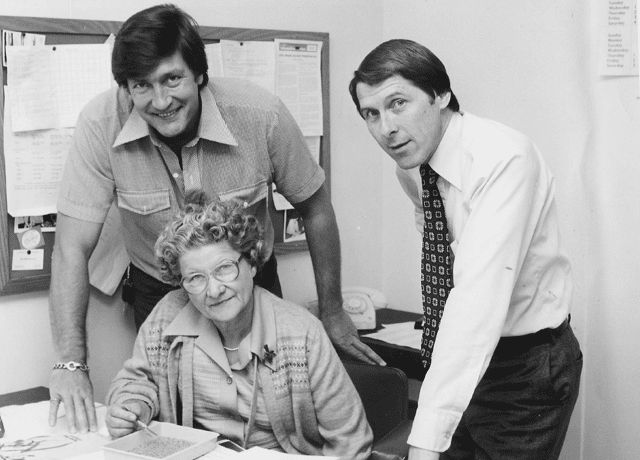

Rees and his experienced team on both sides of the Tasman admit that the exciting future for the new chemical wood preservative entity springs from a past that is equally exciting.

This can be traced back to the Hickson Timber Impregnation Company, which entered Australia in 1956 by way of Hickson New Zealand, set up in the 1940s as a subsidiary of Hickson UK. It operated as a single entity in Australia until 1973 when Koppers Australia Pty Ltd (KAP) acquired the Hickson International timber preservation assets in Australia and Papua New Guinea.

This gave KAP timber preservation plants around Australia and a timber chemical manufacturing business producing CCA timber preservatives.

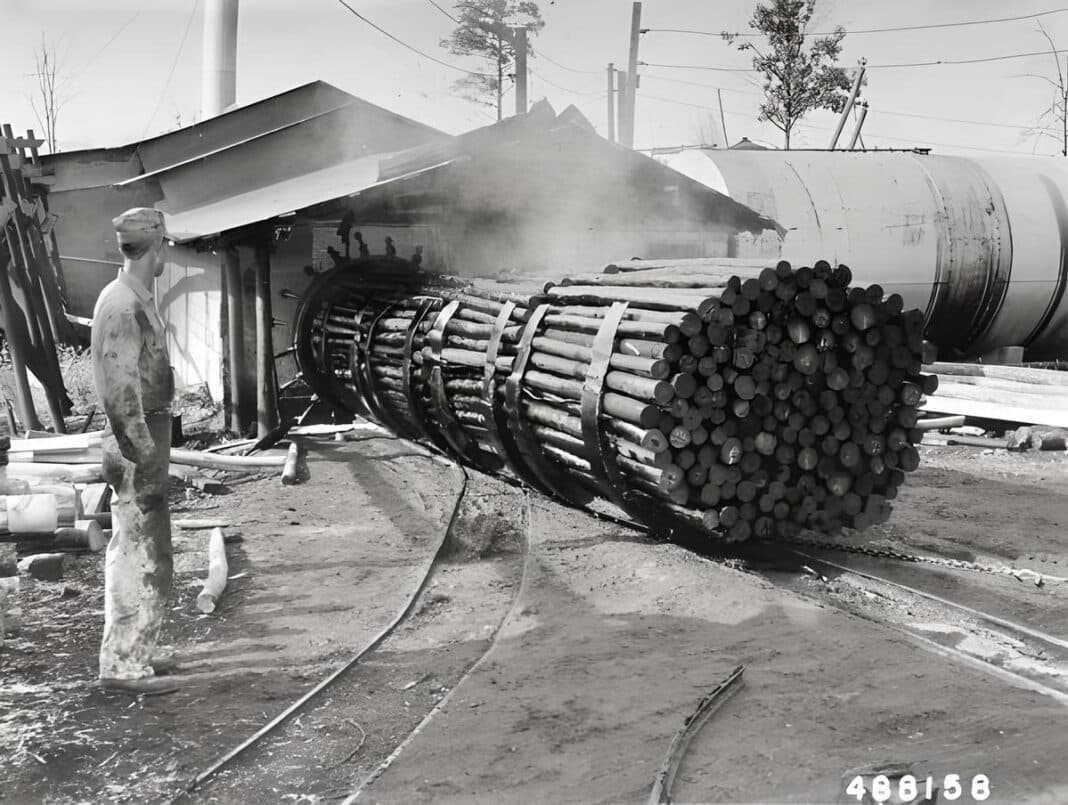

A lot of preservatives have flowed through the cylinders and many pioneers and personalities have come and gone since then bringing dynamic changes for both companies.

The year 1956 stirred special memories for one of the foundation members of the Hickson team in Australia who transferred from New Zealand to set up the operation.

Les Ingles, then a technical officer with Hickson in New Zealand, supervised the first commercial charge of treated timber in Australia, which effectively launched the country’s preservation industry.

“I remember the day well,” Les recalled. “We had a 70 ft long, 30 ft diameter cylinder at our Grafton site stuffed full of hardwood poles. That was in December 1956 and the poles were treated with creosote.

“I still have the photograph and Hickson’s general manger in Australia Eric Fogl (an Austrian) was there along with Fred Duncan, chief of G.A. Duncan.

“We all had our fingers and everything else crossed because it was only a trial, and Eric had invited politicians and the media to the historic event. It all came out fine, thank heaven,” Les said.

Ducan’s, which had the hardwoods poles, was the business opportunity for Hickson to set up in Australia. This was an 85% Hickson-15% Duncan’s deal reached between Fred Duncan and Ian Tudehope, then Hickson New Zealand’s managing director.

The original Hickson team in Australia was Eric Fogl, Fred McDonald, an engineer from New Zealand, Les Ingles, Tim Beeney, an accountant, and, shortly after, Trevor Nash, a chemist from New Zealand.

Les Ingles arrived in September 1956 in time to supervise completion of the Hickson plant at Grafton. He went on to design and launch treatment plants at Wauchope, NSW, Trentham, Victoria and Longford, Tasmania.

“In fact, because of the high cost of using creosote in Tasmania, we moved to CCA for hardwood pole treatment, which means Longford, near Launceston, using Tanalith C imported from Hickson UK, was the first CCA plant to operate in Australia,” Les said.

Eric Fogl was succeeded in 1957 by John Moss who was joined the same year by Ken Rudling, marketing manager.

“Real gentlemen and professionals,” Les Ingles said.

Another early Hickson personality Geoff Patching recalls the company’s establishment in Asia.

“I was in the New Zealand Forest Service when Hickson UK asked Hickson NZ to set up operations for the group in Malaya [now Malaysia] in the late 1950s,” Geoff said. “They wanted someone with a technical background, and he had to be a bachelor because of the insurgency problems there at the time – it was no place for a woman, they said – so I ‘enlisted’ with Hickson.

“That gave Hickson operations in New Zealand, Australia, South Africa, Malaya and Singapore. And at one time, Hickson UK took over the wood preservation manufacture business from Koppers Inc and renamed it Hickson Chemical USA.”

Dan Price, who also worked with Hickson in New Zealand and set up a laboratory for Hickson in Australia, stayed with the company through to the joint venture. He agrees that the Arch arrangement mirrored the Hickson setup where a single entity once again operates independently in the industry.

“Hickson was a wholly-owned UK company based in Yorkshire with its principal interests focused on chemicals for the textile industry. It was their involvement with arsenic out of Scandinavia that took the company into wood preservatives and using their connections in the old empire, they established businesses in the antipodes.”

Koppers Australia Pty Ltd was incorporated on February 28, 1967, as a 50/50 joint venture between Koppers Company, Inc. (KCI) of Pittsburgh, Pennsylvania, USA, and the Broken Hill Proprietary Company Ltd (BHP) of Australia, formed to build and operate a coal tar distillation plant at Newcastle, NSW, a bi-product of which was creosote. KCI at this time was the largest distiller of coke oven tars in the US.

In October 1973, Koppers Australia acquired timber preservation assets in Australia and PNG previously owned by Hickson International of the UK. This gave KAP timber preservation plants around Australia and a timber chemical manufacturing business producing CCA preservatives.

In 1989, Koppers was purchased by Beazer Industries, which sold the Wolman division to Hickson UK. (The US operation was named Hickson Corporation).

The ‘Wolmanized’ name originated with Dr. Karl Wolman, a German pioneer in wood preservation. ‘Wolmanzied’ wood was used in North America and Europe from the early 1900s. In parts of the world, ‘Wolmanized’ remained the property of a German company, and so ‘Tanalised’ and ‘Tanalith’ were used outside North America and parts of South America.

The preservative at that time – FCAP, not CCA – was distributed in the US by American Lumber and Treating Co (ALT), probably starting in the 1920s. ALT’s preservative business was purchased by Koppers Co in 1954. Early uses for ‘Wolmanized’ wood were industrial and commercial – timbers for mines and other structural uses. Decks and outdoor residential uses did not emerge until the 1970s.

In 2000, Arch Chemicals, Inc., a spin-off in 1999 from the specialty chemicals component group Olin Corporation, acquired Hickson International. Hickson Corporation became Arch Wood Protection, Inc, and the wood treatment operations in Europe became Arch Timber Protection and, eventually, Koppers-Arch in Australia.

The recession of the early 1990s forced Olin to pare down its diverse mix of businesses. By the end of 1995, Olin sold or simply closed 18 businesses and product lines to focus on three core activities – chemicals, defense, and metals.

The name Arch Chemicals, Inc. (derived from the curved archway structure capable of spanning a space while supporting great weight) was selected in August 1998 and the new entity was incorporated in Virginia, although its headquarters would be established in Norwalk, Connecticut.

Heads of the new company were selected from Olin’s executive ranks and Olin executive vice-president Michael E. Campbell was appointed chairman and chief executive of Arch.

“The acquisition of Koppers-Arch is a key component in our international wood preservatives business expansion strategy,” Michael Campbell said. “It nicely complements our existing business and provides excellent geographic expansion opportunities in Asia.

“In addition, we have a number of exciting new products, services and technology developments that we plan to introduce to China and other Australasian markets.”

Together with its subsidiaries, Arch has about 3000 employees and manufacturing and customer-support facilities in North and South America, Europe, Asia and Africa.

In 2000, Arch paid US $140.4 million for Hickson UK, a move that strengthened Arch’s global position in high-growth biocides and performance urethanes.

The Arch group now produces and markets a full line of wood preservative products tailored for the wood processing and forestry industries in Australia, New Zealand, South Africa, Asia and the Pacific Islands.