Pritzker Prize-winning architect Shigeru Ban is behind a new version of the Paper Log Cabin, using a special Paper Partition System (PPS) prototype deployed in evacuation centres to house victims of the February 2023 Turkey-Syria and September 2023 Morocco earthquakes.

According to Mr Ban, who is also behind a Styrofoam Housing System (SHS) now used by Ukrainians displaced from the Russian war, the shelters took three people and just five minutes to build.

Mr Ban, who founded the Voluntary Architects Network 30 years ago, considers himself a humanitarian first and foremost. He has provided temporary housing, partition systems, community centres, and places of worship for those affected by natural disasters and conflicts in Rwanda, Syria, Turkey, India, China, Italy, Haiti, and his home country of Japan.

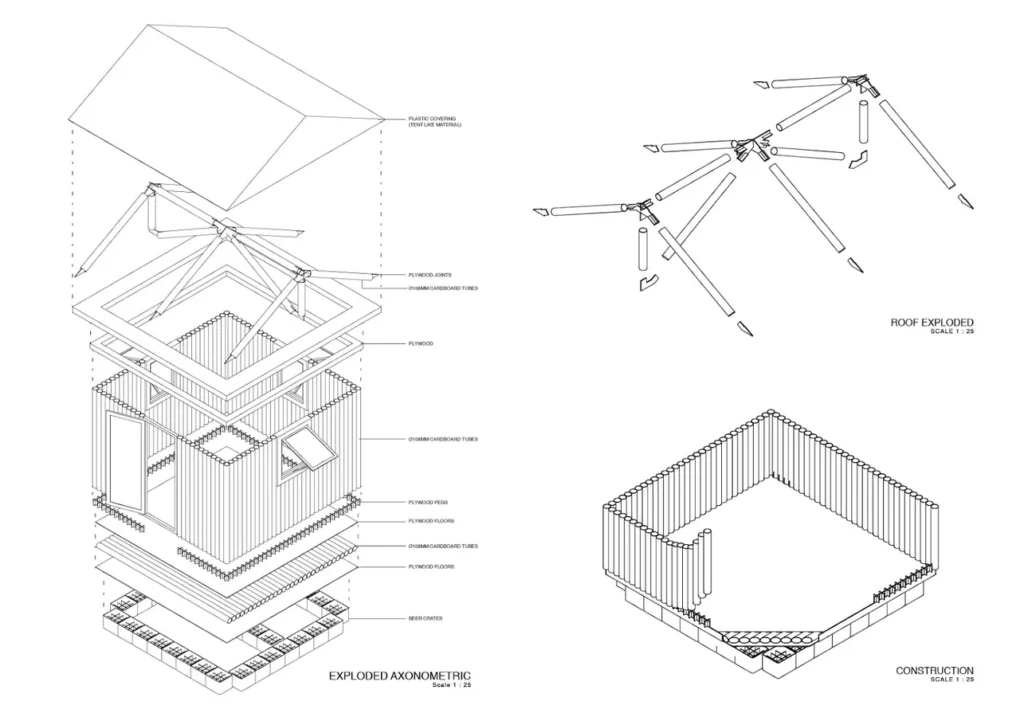

Wood Central understands that the cabins are raised atop beer crates primarily constructed from paper and wood. Their rapid assembly process makes them an ideal solution for temporary shelter in multiple disaster-prone regions, including Japan and Korea.

“Architects are not building temporary housing because we are too busy building for the privileged people… I am not saying I am against building monuments, but I think we can work more for the public,” said Mr Ban, who revealed an updated version of his 1995 design last year.

Paper Log Houses allow for rapid assembly and disassembly

The Paper Log House has several vital parts that meet the demands of earthquake victims. It is not only economical, using materials that are (largely) easily obtainable, but its simplistic design means that unskilled labourers can build it.

In addition, once the disaster is over, the houses can be easily dismantled, recycled, and upcycled, preventing the government from spending vast sums of money on clean-up.

“If a building is loved, it will become permanent,” Mr Ban told Arch Daily, adding that the challenge lies in the notions of permanence and material strength.

Dating back to 1985, Mr Ban’s connection to paper tubes has evolved into a pioneering exploration of the material’s construction. The architect has used paper tubes in installations, buildings, and disaster relief projects, including the 79-foot-tall Cardboard Cathedral, now a permanent landmark.

How the Paper Log Houses are constructed

Wood Central understands that the Paper Log Houses are typically 13 feet by feet and consist of beer crates, sandbags, plywood, cardboard tubes, waterproof tape, and steel rods. According to Re-Thinking the Future, “the advantages of materials like paper tubes include that they are durable, recyclable, reusable, biodegradable, and non-toxic.”

The foundation of the Paper Log House is made flood-resistant by using about four rows of beer crates. This is followed by a layer of plywood for the flooring, which is secured in position by pegs arranged on the edge of the flooring. 106mm in diameter and 4mm thick cardboard tubes are placed on the flooring in the position of walls, with 13-foot rods placed horizontally in the tubes to provide additional support to the structure.

A plywood frame with tent-like material is bound to the frame as part of the roofing system. The roof is mechanized so it can be operable under climatic conditions, treated as a separate element from the rest of the shelter so air can circulate during summer and warm air can enter in winter.

- Shigeru Ban has been named Laureate of 2024 Praemium Imperiale For Architecture, click on Wood Central’s special feature to find out more.