Just 2.5% of wood is upcycled and reused in construction projects, with almost 90% of wood-based products “downcycled or destroyed” in construction.

It comes as wood-based products are under increased scrutiny as building and construction supply chains grapple with the push to greater circularity and decarbonisation.

Most investment has been in the wood processing supply chains, where new technologies are used to upcycle low-value products and produce higher-value products such as reconstituted bamboo or laminated veneer lumber products.

However, irregularly shaped wooden offcuts, created as part of the construction process, have been largely ignored “because of its complicated geometry and a lack of well-defined design methods.”

That is until now.

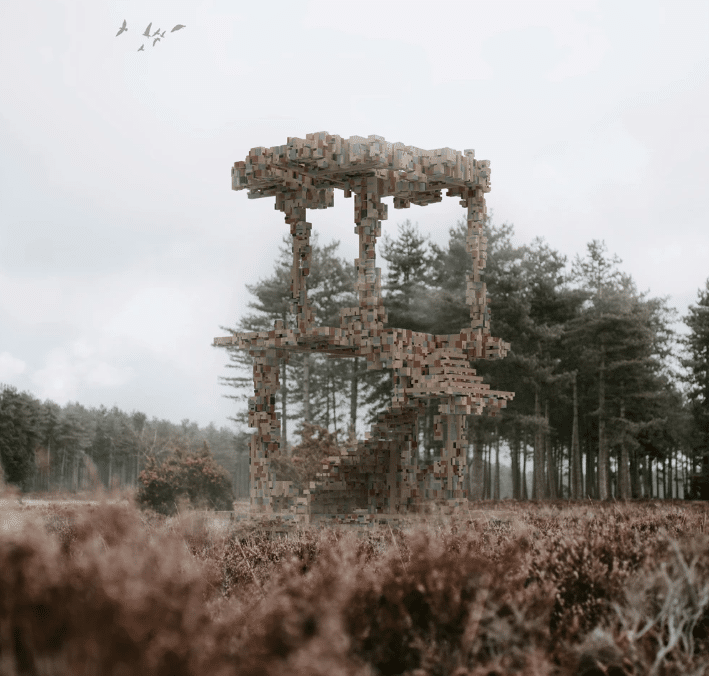

Using 3D scanning and material screening, scientists have developed a systematic approach that could lead to a far greater optimisation of wooden offcuts in furniture, building materials, regenerative design, and construction projects.

It proposes greater use of autonomous construction technologies, including robotic assembly and AR-aided assembly methods, to sort through materials and identify offcuts for reuse.

Published in Nature, global researchers from China and the UK have, for the first time, established a “Framework for sustainable building design and construction using wooden offcuts.”

Led by Boyuan Yu from the Chinese University of Hong Kong, researchers developed a new system for repurposing a range of products, including MDF, chipboard and biomass energy.

Supported by scientists from the University College, London, Mr Yu found that “fewer than 20% of construction projects had established databases for recycled materials.”

Accordingly, Mr Yu proposes a rethink of how different scales of waste wood, from edge scrap to building components, can be reused in building design and fabrication.

He points to the surge in demand for reclaimed timber, expected to grow by 20% over the next five years as part of increasing environmental awareness, inclination to recycle and push to improve waste management systems.

“Reclaimed wood is a sustainable material with a renewable and unique customised nature,” he said, “and the reclaimed wood esthetics and urban wood esthetics make recycled wood products stand out from the competition in recycled products.”

The new model, the sustainable building design construction (SBDC) framework, demonstrates how offcuts can be reconfigured and reused in joinery, furniture, panels and structural timber products.

“The SBDC framework integrates green technologies with a multidisciplinary approach to sustainability, computer science, design and manufacturing, and materials science,” Mr Yu said.

Reviewing operations at five sawmills across London, the study found errors with the improper disposal of offcuts, including a lack of data and classified storage.

“Large amounts of wood were exposed and uncovered in the outdoor environment, which resulted in varying degrees of damage from insect infestation and its eventual waste,” according to Mr Yu.

Thus, the study proposed developing a digital recording method, which “allows for a more comprehensive 3D data capture process for irregular reclaimed wood.”

The byproduct is that timber, with irregular cross-sectional size, is all too often incorrectly classified as “waste wood”, which has led to the destruction of “valuable recyclable materials,” which, according to Mr Yu, “is a waste of resources we cannot afford.”

“Many materials are regarded as firewood sold on eBay and other platforms or downgraded and made into plywood, or the waste wood is disposed of by burning, causing resource waste and environmental pollution.”

These offcuts are typically used in manufacturing and designing projects with superficial geometric characteristics and categories.

“Those with the same section are considered regular easy-to-reconfigure offcut wood that can be built into furniture and installed through simple reconfiguration.”

However, with the help of computer science, “it is possible to generate a simulation of the assembled structure for wood species with the same section size, approximate weight density, and approximate moisture content.”

“This offers more possibilities for reclaimed offcut wood assembly solutions” and provides “statistical analysis of the generated structures, which contributes to easily comparing the overall quantity and types of materials used in different developed solutions.”

Reflecting on the work, Mr Yu said the systems proposed in the study “are reproducible.”

“It provides a technical workflow to support the design generation and construction of furniture, installations, and buildings at different scales and helps to preserve wood resources that are becoming scarce.”

The furniture industry has driven the push for greater optimisation of wooden offcuts.

The furniture segment leads the global market with a share of 31% and is projected to witness continued growth through 2028 – with the global government’s pushing for greater circularity in supply chains.

In November last year, Australia became the first country in the world to commit to a fully circular economy by 2030, with Forest and Wood Products Australia (FWPA) revealing to Wood Central the importance of recycled timber in various applications, such as construction, furniture, and decoration, helping to minimise waste in driving the aims.

According to research commissioned by North Carolina State University, urban and reclaimed wood inherently fits within a circular economy.

Noting that “The reclaimed wood industry extends product life by remanufacturing previously utilized components from old structures, and the urban wood industry produces as-new, value-added products using salvaged urban logs as raw material input.”

The study published in the BioResources journal found that greater education and regulatory support were required to promote urban and reclaimed wood utilisation.

“However, with proper education, a majority of stakeholders see the value in production with these resources over landfilling, whether through the sale of logs to local firms for value-added production or through chipping, firewood, or other low-value uses,” the study concludes.