The residential variety across Amsterdam city is stunning. Some rents are high, but many more are controlled and affordable by non-profit associations that deliver the bulk of housing in the Netherlands.

This includes the De Warren project, representing a fresh approach to sustainable living as the city’s first ‘self-build housing cooperative.’

The project encompasses 36 apartments aimed at social and affordable rental housing. The development boasts an ‘EPC’ (Energy Performance Certificate) rating of -0.16, classifying it as an energy-positive building, meaning it offsets more carbon than it consumes.

The project was designed by Natrufied Architecture, a Dutch design practice specializing in biophilic design, with engineering provided by Pieters Bouwtechniek.

Last month, De Warren was awarded the Amsterdam Architecture Prize for 2023.

According to a statement attributed to the practice, “The core idea of De Warren is collective living. With the help of a series of workshops with the future residents, it was decided that 30% of the building should consist of collective spaces.”

This creates approximately 800m2 of communal functions (with a total Gross Floor Area of 2,400m2), including a large auditorium, a multifunctional room, a children’s playroom, a music studio, various co-working places, a meditation room, a greenhouse, a roof terrace, and several communal living rooms and kitchens.

The collective spaces are arranged along the so-called ‘Machu Picchu’ staircase that connects all floors. By placing the collective spaces centrally, they become part of everyone’s daily route, maximizing contact between residents.

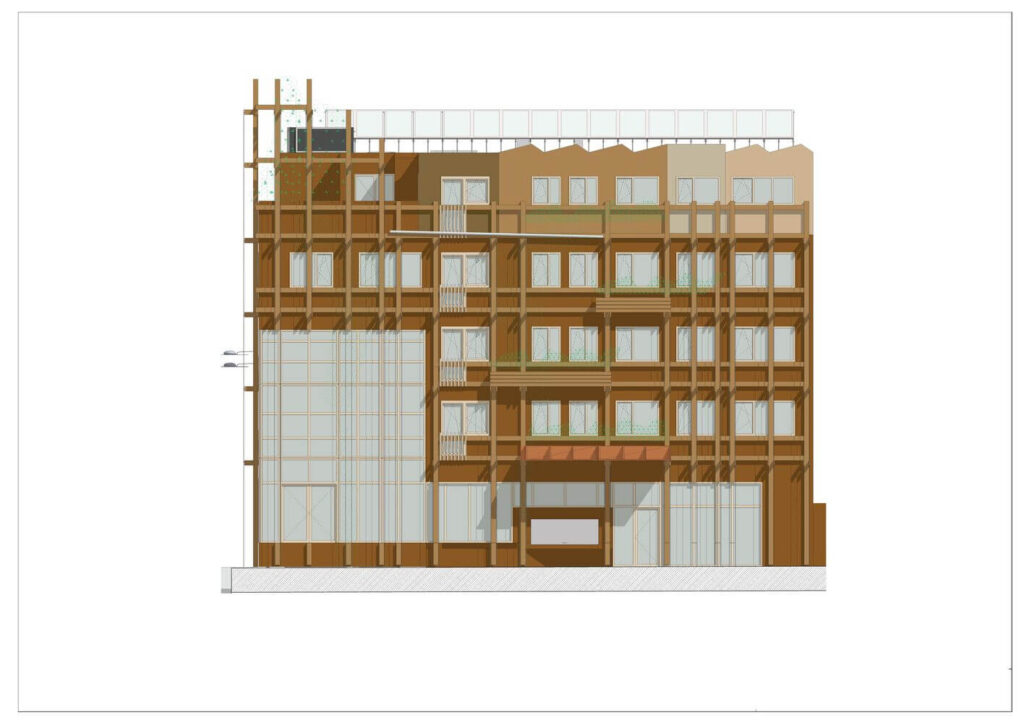

Reclaimed façade

To meet its sustainability commitments, the project prioritized using timber-based building materials wherever feasible – specifically Azobe and Basralocus.

The facade cladding is made of recycled retaining walls (Azobe). The harvested planks were first doubled before they had the right thickness for use as facade cladding.

The ‘mikado’ front facade for balconies and a nature-inclusive approach (with planters that use rainwater from the polder roof) is made of recycled bollards (Basralocus).

For the wooden facade finishes, together with the cross-laminated timber supporting structure, the wood-frame facade elements, window frames, and interior walls, a total of 330 m3 of wood was used, which has stored more than 300 tons of CO2 during its lifetime. This is equivalent to approximately 200 years of emissions from the average car in the Netherlands.

Using technology to maximise recovery of recycled timber

One significant challenge was to repurpose large bollards into individual façade elements. The process demanded a careful match between the supply of elements (provided by sawmills, material hubs, and demolition companies) and the specific demand of De Warren’s design. Summum Engineering rose to this challenge by developing a parametric model.

This sophisticated model provided insights into the required volume and size of bollards. The algorithm then determined the most efficient method for sawing each façade element from the hardwood bollards. This model was instrumental in reducing cutting losses and material waste while delivering a cost estimate based on supplier and sawmill data. In the end, it helped derive an optimized sawing schedule.

Breathing a Second Life into Timber

The success of De Warren in creating a completely circular façade can be attributed to the close coordination among the project team. The process of repurposing reclaimed bollards, although time-consuming and challenging due to unexpected flaws like cracks and holes, proved ultimately rewarding.

De Warren repurposed as much timber as possible by harnessing the collective expertise of demolition companies, sawmills, and timber specialists. As a result, De Warren’s project emerged as more than just a sustainable housing solution – it gave a second lease of life to materials that would have otherwise been wasted.