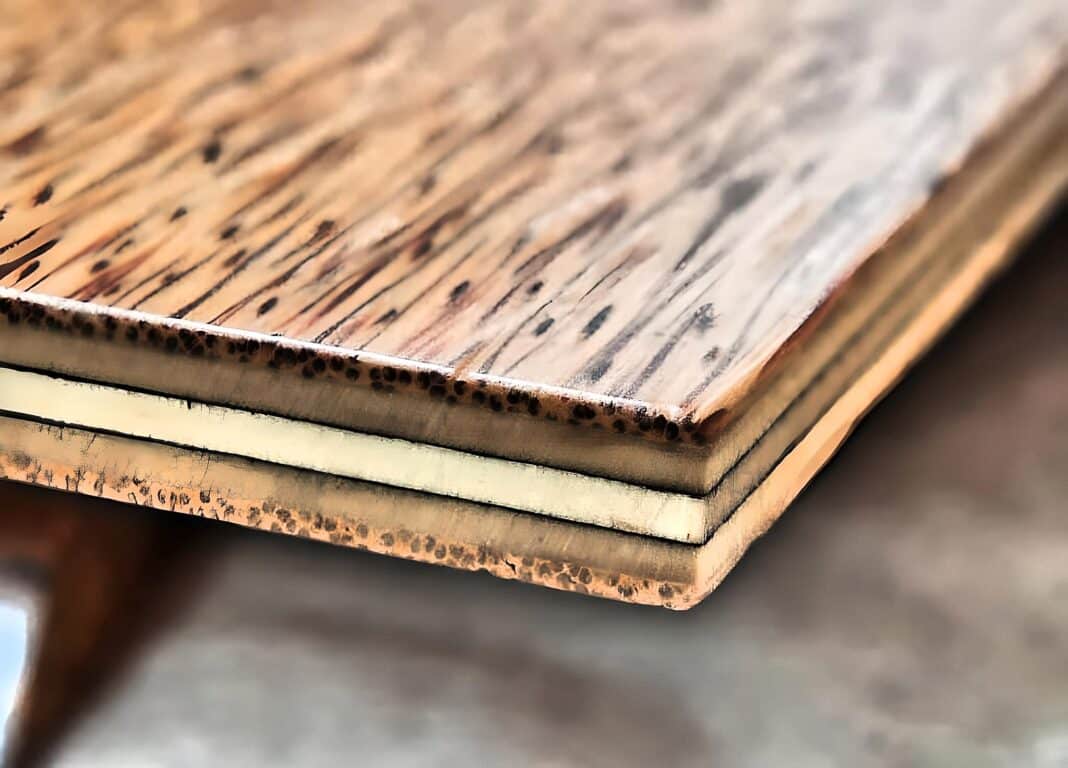

The process of extracting rotary veneer from coconut palms and making engineered wood products might seem like a nutty idea, but according to QDAF Research Facility and Project Manager Dr Rob McGavin this product, known as ‘Cocowood’ or ‘Cocoveneer’ has the potential to enhance lives across the South Pacific.

Led by QDAF, the process draws on research from several projects commissioned by the Australian Government’s Australian Centre for International Agricultural Research (ACIAR).

Dr McGavin explains:

“Coconut farming is a major contributor to the livelihoods and economies throughout the Pacific Islands.”

“Our research has focused on senile plantations that is aged coconut palms, which require removal for renewal and replanting.”

Coconut palms suffer from a major reduction in nut productivity once they reach about 60 years and require safe removal and replanting to rejuvenate the crop.

The presence of coconut rhinoceros beetle means that coconut palms must be regularly monitored for health and well-being, with sick or harvested palms removed to prevent further infestation.

The removal and replanting of palms can be costly. Creating demand and a market for logs to extract veneer from the aged palms can provide communities with a much-needed cost recovery.

“Through a series of projects, we have provided valuable information about the characteristics of coconut woody tissue and different processing equipment that can be used to produce and dry rotary veneer and make products from the veneer.”

“One of the many challenges that remain is identifying some markets for the end-product,testing economics and social factors along the value chain and supporting commercial adoption,” Dr McGavin said.

“This will be the focus of the latest 5-year project supported by ACIAR, QDAF, Pacific Communities (SPC), University of Queensland, Griffith University, PHAMAPlus, Fiji Ministry of Forestry, along with Australian and Pacific industry partners.”

“In Queensland, we have a range of natural and plantation-grown subtropical timber species, which like coconut palms, can be highly conducive to producing highly valuable rotary veneer,” Dr McGavin said.

Using spindle-less veneer peeling and cutting technology, previously unsuitable timber resources can now be processed into high-value veneers.

Just like the coconut story, the creation of a viable market for these resources can help fund much-needed forest management systems, including thinning, and supply unique high-performance engineered wood products to high-value markets.

Spindleless peeling allows for greater recovery from smaller diameter logs and reduces the processing problems previously experienced with small fast-grown trees.

This has particular relevance to Queensland silvopastoral lands, where private landowners can reap the cost recovery from trees that were not otherwise suitable for processing.