Stronger than plastic and tougher than glass, “transparent wood” could soon become the default material for every smartphone worldwide!

If successful, the material could rival biomass and pulp, paper and packaging to become the world’s largest forest product and greatly assist in the push to drive circularity across the fast-moving consumer goods market.

According to researchers from the KTH Royal Institute of Technology in Sweden and the University of Maryland in the US, the resin-filled timber skeleton is three times stronger than Plexiglss and ten times stronger than glass crystals – with businesses starting to commercialise the technology.

The material, which draws upon more than 30 years of research, was discovered by a German botanist, Siegfried Fink, in 1992, before Lars Berglund, a Swedish researcher, expanded its use in the early 2000s.

Now, the research is starting to bear fruit after more than two decades of experiments and more than a decade since their original study was published. Professor Berglund is confident the material will be used in “super-strong smartphone screens, in soft, glowing light fixtures, and even structural features, such as colour-changing windows.”

“I truly believe this material has a promising future,” according to Qiliang Fu, a wood nanotechnologist at Nanjing Forestry University in China who worked in Berglund’s lab as a graduate student.

As reported in Scientific American last month, the process created a resin-filled timber by modifying or removing lignin from tree cells. This glue-like substance holds the tube-like cells that transport water and nutrients throughout a tree together and helps give the tree its brown colour. The researchers then removed or bleached the lignin to remove the colour and filled it with epoxy resin to render it transparent.

Is transparent wood the solution for easily shattered smartphone screens?

The potential market for the product is enormous – with demand for smartphone display screens alone expected to reach US $125 billion over the next decade – with displays made from layers of plastic and glass as part of a liquid crystal display. Added to this are insulated windows, mirrors and glazed doors.

The material is thin – between 1mm to 1cm in thickness, “but the cells create a sturdy honeycomb structure, (with) the tiny wood fibres stronger than the best carbon fibres,” according to Liangbing Hu, a material scientist from the Unversity of Maryland, who leads the US-based research into the material.

“The results are amazing that a piece of wood can be as strong as glass,” says Professor Hu, who highlighted the features of transparent wood in the 2023 Annual Review of Materials Research.

The process can work with thicker wood; however, visibility through the material impairs the view as light scatters between the wood.

In the original study, in 2016, Professor Hu and Professor Berglund found that millimetre-thin sheets of resin-filled wood skeletons let through 80 to 90% of light. However, as the crystal’s thickness gets closer to a centimetre, light transmittance drops, with Professor Berglund reporting that a 3.7-millimetre-thick piece of wood transmitted just 40% of light.

The slim profile, strength and durability of the material could make it an alternative to thin, easily shattered cuts of plastic and glass used in display screens – with its robustness reducing instances of cracked screens.

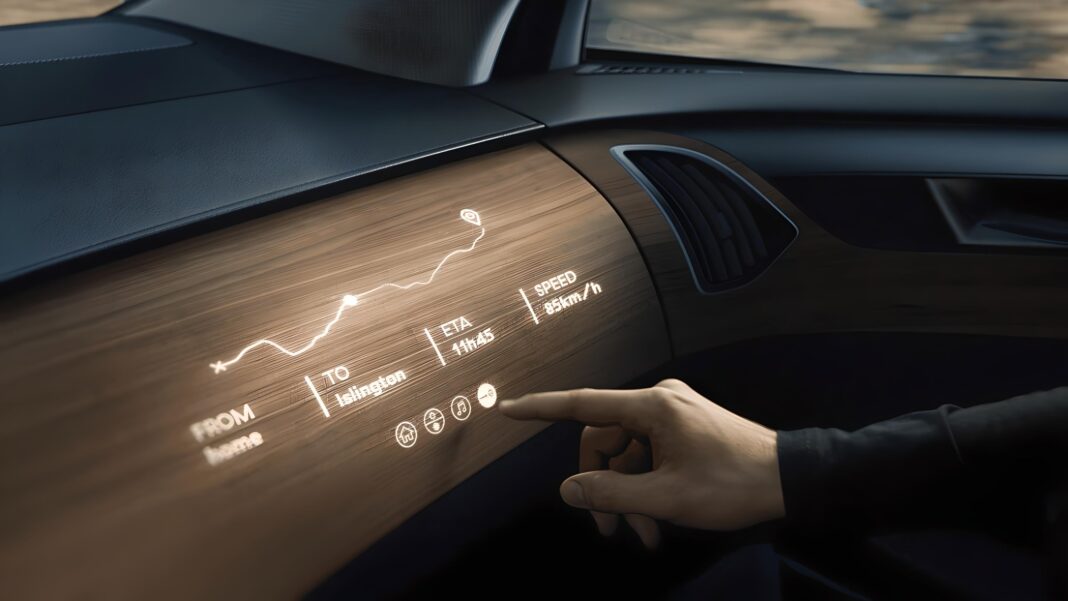

Already, French-based Woodoo is using lignin-removing resin technology to create recyclable, touch-sensitive digital displays used in car dashboards and advertising billboards.

Already transparent wood outperforms glass for energy efficiency

However, most research has centred on using the material in buildings, with windows showing the most promise, according to Prodyut Dhar, a biochemical engineer at the Indian Institute of Technology Varanasi.

“Transparent wood is a far better insulator than glass, so it could help buildings retain heat or keep it out,” Professor Dhar said.

Already, Professor Hu is using polyvinyl alcohol, or PVA — a polymer used in glue and food packaging — to infiltrate the wood skeletons, making transparent wood five times more energy efficient than glass, according to research published in the Advanced Functional Materials publication.

Researchers are developing more tweaks to increase wood’s ability to hold and release heat, driving building energy efficiency.

Céline Montanari, a materials scientist at RISE Research Institutes of Sweden, is experimenting with phase-change materials, which flip from storing to releasing heat when they change from solid to liquid.

She said that by incorporating polyethylene glycol, wood could store heat when it was warm and release heat as it cooled. Adding transparent wooden windows would be more robust and improve temperature control than traditional glass, “but the view through them would be hazy, more similar to a frosted glass than a regular window.”

Nonetheless, she said haziness could be an advantage if users want diffuse light: “Since thicker wood is strong, it could be a partially load-bearing light source”, according to Professor Berglund, who said that transparent wood could act as a ceiling providing softer, ambient light.

Could the material fuel a surge in “smart window technology?”

According to Professor Berglund, transparent wood can mimic smart windows, “which can switch from transparent to tinted to block visibility or the Sun’s rays.”

In recent years, demand for smart windows technology has surged, with voice-assisted home technologies fuelling a multi-billion dollar industry for motorised and connected window coverings.

Sandwiching an electrochromic polymer — a substance that can change colour with electricity — between layers of transparent wood, Professor Berglund and researchers from US-based Georga Insitute of Technology created a pane of wood that changes from clear to magenta when users run a small electrical current through it.

More recently, the two groups have shifted their attention to improving the sustainability of transparent wood production. For example, “the resin used to fill the wood scaffolding is typically a petroleum-derived plastic product, so it’s better to avoid using it”, according to Professor Montanari.

As a replacement, researchers have invented a fully bio-based polymer derived from citrus peels. Combining acrylic acid and limonene, a chemical extracted from lemon and orange rinds found in essential oils, researchers impregnated delignified wood inside the polymer.

Even with a fruity filling, the bio-based transparent wood maintained its mechanical and optical properties, withstanding around 30 megapascals of pressure more than regular wood and transmitting around 90% of light, according to research published in Advanced Science back in 2021.

Professor Hu’s lab, meanwhile, is advancing a greener lignin-bleaching method that leans on hydrogen peroxide and UV radiation, further reducing the energy demands of production.

The team brushed wood slices from about 0.5 to 3.5 millimetres thick with hydrogen peroxide, then left them in front of UV lamps to mimic the Sun’s rays. The UV bleached away the pigment-containing parts of lignin but left the structural parts intact, thus helping to retain more strength in the wood.

These more environmentally friendly approaches help limit the amount of toxic chemicals and fossil-based polymers used in production. However, for now, glass still has lower end-of-life environmental impacts than transparent wood, according to an analysis by Professor Dhar and colleagues in Science of the Total Environment.

Researchers say embracing greener production schemes and scaling up manufacturing are two steps necessary to add transparent wood to mainstream markets, but it will take time. However, they are confident it can be done and believe in its potential as a sustainable material.

“When you’re trying to achieve sustainability, you don’t only want to match the properties of fossil-based materials,” Montanari says. “As a scientist, I want to surpass this.”