The Marylebone Cricket Club (the MCC) has approved the final stage of Lord’s modernisation. Last week, members voted in favour of £61.8 million plans to rebuild the Tavern and Allen Stands.

The latest work, Stage 3, comes after the MCC previously spent £53m fully rebuilding the Compton and Edrich Stands (Stage 2) in 2021.

In announcing the plans, Robert Ebdon, MCC Estates Director, said, “The redevelopment will complete our stand development programme,” which, once finalised, will meet BREEM’s “Excellent Standards,” which Mr Ebdon said “strengthens the MCC’s impressive sustainability credentials.”

Work on the stands will begin later this year, pausing for the cricket 2025 and 2026 cricket seasons before fully finishing in time for the 2027 Ashes Series.

Yesterday, the MCC appointed John Graham Construction as a contractor for the works, who will subsequently work with architect WilkinsonEyre and consultants Buro Happold, Gardiner & Theobold and Arcadis on the final stage.

Jim Eyre, Founding Director at WilkinsonEyre, is “delighted to continue our successful partnership with MCC,” stressing that “the new designs will add great value to this world-famous sporting venue, modernising and improving the existing facilities for its members.”

The redevelopment will see an extra tier added to both stands, boosting the stadium’s seating capacity by at least 1,100 more seats. In the Allen stand, the current scoreboard will be moved, while in the Tavern stand, a new cantilevered level of seating on the fourth level will be added, extending back to the site boundary.

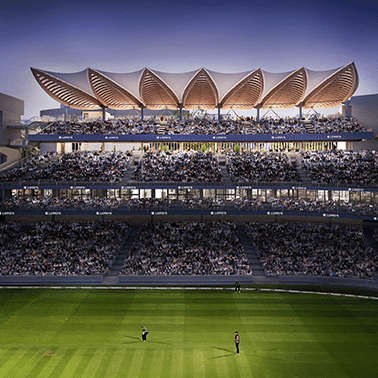

Wood Central understands that, like the Compton and Edrich Stands, also designed by WilkinsonEye, both stands will incorporate a hybrid of mass timber and steel. The Tavern Stand (which will retain its steel frame) will use a roof design “inspired by the shape and ribbed construction of a series of upturned traditional slip cradles,” a key part of Lords’ theme.

The Allen Stand, dating back to the 1930s, will be demolished and replaced with a new stand. In addition, a link bridge between the Allen Stand and the Pavilion will be demolished and rebuilt in the upper tier, a move welcomed by Members.

According to Rob Joyce, Development Director at John Graham Construction, the new project will be “transformational” for the world’s most famous cricket ground. “Together, we aim to enhance the Members’ and public spectator experience, expand capacity, and usher in a new era at the iconic Home of Cricket.”

Introducing the Lord’s Masterplan

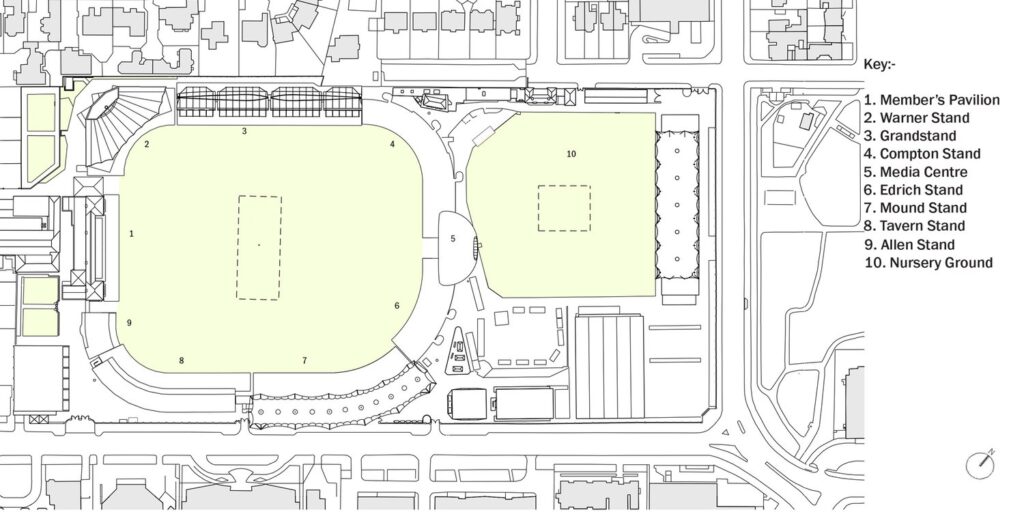

The new work is the final part of a decade-long plan set out in 2013 when the MCC released the Lord’s Masterplan – it saw the MCC update and modernise five of the grounds’ six grandstands, including the Warner Stand (Stage 1), the Compton and Edrich Stands (Stage 2), and now the Tavern and Allen Stands (Stage 3).

After extensive study, Mass Timber was selected as a preferred building material for the three grandstands in the first two stages, underpinned by Lord’s commitment to low-embodied carbon building materials.

With the addition of solar panels, the grandstands not only utilised low-carbon building materials in construction but also reduced emissions during operation—the stadium is now operating off 100% wind power.

A major consideration was the activation of key precincts around the Grounds – including the Village Green at the Nursery End and the Coronation Gardens at the Member’s End.

In addition, the master plan aims to improve sightlines, enhance the spectator experience, and create a more inclusive space to broaden cricket’s appeal.

Stage 1: The Warner Stand (2016)

The Warner Stand, which has a capacity of 2,668, is located in the western corner of Lord’s Cricket Ground, next to the Pavilion.

Designed by Populous, the stand features a wing-like roof formed using white oak glulam beams and profiled steel. Its high-tech translucent fabric canopy shades spectators and allows natural light.

Manufactured by Hess Timber, certified to both FSC and PEFC standards, the stand used 50 square metres of glue-laminated American White Oak timber (supplied by Robinson Lumber Company), with beam lengths of up to 25 metres and cantilever beams of up to 12.2 meters.

Locating and securing the cantilevered glulam beams – at that time, the longest ever created using American white oak – was no easy task.

According to the American Hardwood Export Council, “100 cubic metres of Number 1 Common grade American white oak was used to create the 11 beams for the stand. The AHEC Grown in Seconds sustainability calculator shows that the volume of timber used for the beams would take just 160 seconds to regrow in the forest.”

Stage 2: The Compton and Edrich Stands (2021)

The stands sit on either side of the J.P Morgan Media Centre at the Nursery End of the ground, directly opposite the pavilion’s wooden benches.

The stands are unique in that they cater almost exclusively to the general public (and not the MCC members), with the stands opening out to the Village Green behind the Ground.

Designed by WilkinsonEyre, both have a combined capacity of 11,600. More than half the seats have been reused to reduce landfill waste.

The grandstands feature canopy roofs and at 24m high, tower above all other grandstands. They both provide unrivalled views of the field of play and panoramic views beyond the ground across London.

The canopy consists of a combination of white-painted radiating steel ribs, a visible timber supporting shell on the underside, and white fabric skin. Manufactured by Constructional Timber, the shell was assembled using PEFC-certified Glue Laminated Timber.

- To learn more about the Lords Ground Development, visit the Lords Cricket Ground website.