By 2028, mass timber construction buildings of up to 20 stories could become economically and technically feasible.

Thanks to new materials and technology developed by Dr Tony Yang, “the next generation of mass timber construction will mark a turning point in how we build in this country and potentially in the world.”

As reported by Construct Connect, Dr Yang, a civil and mechanical engineering professor at the University of British Columbia (UBC), is pushing to develop new products stretching Canada’s current national building code, allowing mass timber construction up to only 12 storeys.

“The next generation of mass timber construction will mark a turning point in how we build in this country and potentially in the world,” according to Dr Yang.

“We’re confident that with these new tools and materials under our belt, we will help Canada meet, if not surpass, its 2030 carbon emissions goals.”

The ‘Next-Gen’ Construction Initiative

Yang participates in The Next Generation Wood Construction initiative (Next-Gen), a partnership between the Canadian wood industry, academic institutions, governmental organisations, and the building industry.

By resetting national building codes for mass timber construction, the programme intends to remove technical and non-technical barriers to the growth of the wood construction industry.

According to Dr Yang, some challenges include a lack of design approaches, performance data, environmental impact assessments, and the need for more qualified people to handle the demands of rising wood consumption.

Next-Gen has four themes:

- Structural and serviceability performance

- Fire safety

- Building envelope and energy performance

- Sustainable construction technologies and practices

“The research consists of advanced simulation, experimental testing and code development,” said Yang.

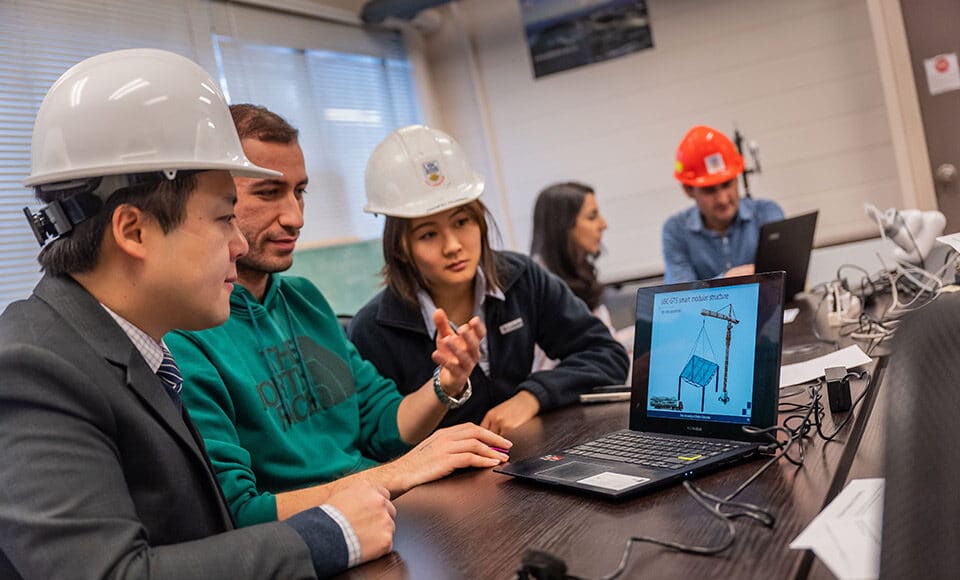

The Next-Gen team comprises 20 scientists, 12 government and commercial organisations professionals, and 31 faculty members from 14 Canadian universities.

The academics and scientists team will supervise 50 qualified trainees “who will actively contribute to our research endeavours.”

Dr Yang and his colleagues at UBC have been working on novel kinds of modular construction to create mass timber buildings that can survive earthquakes while having a smaller carbon impact.

Modular construction, popular in Singapore, the USA, the UK and Canada, has yet to be deployed in areas prone to earthquakes and other seismic activity because it is still a relatively new building technique.

Dr Yang and his colleagues have already created a high-performance mass timber modular building prototype.

“To dissipate earthquake energy, the building will be equipped with higher-performance dampers.”

Dampers protect a building from movement due to pedestrian loading, wind and seismic action.

Motion control from dampers increases structural integrity and the comfort and safety of a building’s occupants.

“The structural components, energy dissipation devices and connections have been tested.”

The next step is to finish the modelling of the entire building.

“Everything we are doing in this project is going to change how we do things in the construction industry fundamentally,” said Dr Yang.

“In five years, we will be able to deploy the next generation of technology to make infrastructure safer, more carbon-neutral and efficient,” he said.

“We will be able to protect people’s lives from the disastrous aftermath you see from severe earthquakes.”

The ‘Shake Table’ is being used to test Mass Timber Buildings in the US

Research on seismic testing of mass timber buildings is also taking place in the US.

As reported by Wood Central, the University of California San Diego has subjected the tallest building ever to be seismically tested, having passed 100 tests last month.

The 10-storey mass timber structure, made mainly of donated mass timber, was constructed for testing as part of the Natural Hazards Engineering Research Infrastructure TallWood Project.

“You’re putting a building through the number of quakes it will never, ever experience unless it’s around for 5000 years,” says Thomas Robinson, founding principal of Lever Architecture.

Recent changes to building codes in the US permit mass timber buildings as tall as 18 storeys (higher than Canada, Australia and New Zealand).

But only now is it known how such high-rises would fare in earthquake-prone areas such as California.

For nearly 20 years, the university has hosted a critical earthquake research tool: a large metal platform that imitates seismic shifts using hydraulics.

According to Popular Science, the “vibration table,” among the biggest in the world, has examined 30+ structures since 2004, impacting building codes and transport rules.