The next generation of wall-to-floor connectors could use fewer bolts, making it easier to relocate, reassemble, and reconfigure ‘flat pack’ mass timber systems in remote areas. That is, according to researchers from the University of Waterloo in Ontario, Canada, designing new plug-and-play fasteners that can help the Canadian government tackle a spiralling housing and affordability crisis.

As part of the Structural Timber and Applied Research Team (or START), members of Waterloo’s Facility of Engineering are looking to expedite the deployment of safe, sustainable, and affordable houses. The system can be transported and assembled without heavy equipment.

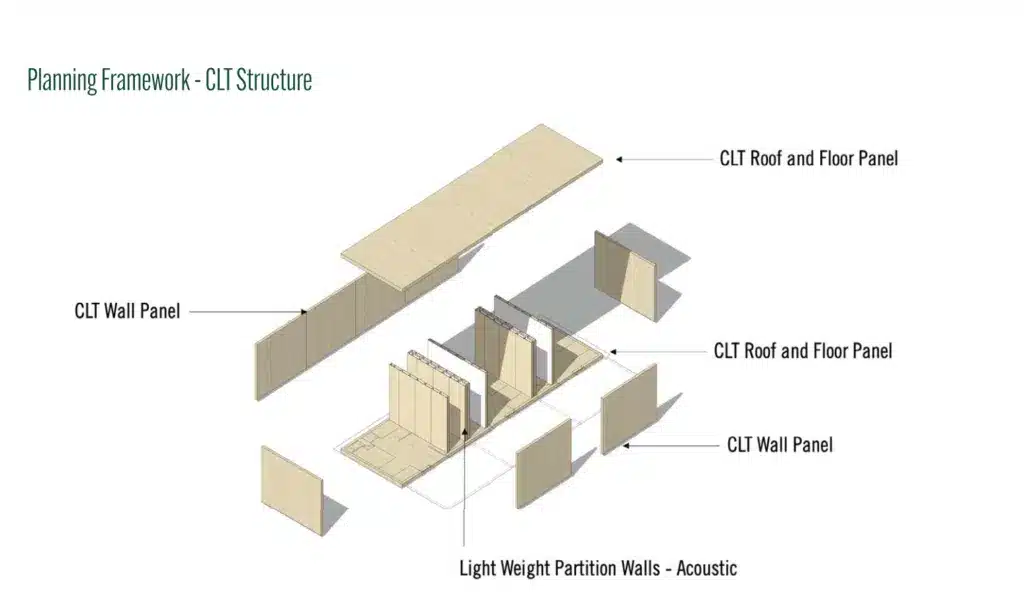

“Our goal is to redefine how modular buildings are conceived and implemented,” said Dr Daniel Lacroix, a professor and lead on the project. “We are leveraging mass timber with other lightweight and sustainable materials to create a system that can be assembled, disassembled and reassembled without compromising structural integrity or affordability.”

Wood Central understands that the new connector runs counter to standard design methodology as it is purposefully designed to allow multiple reuses and relocations. Moving away from using multiple small fasteners closely spaced allowed the team to develop a practical connector for disassembly and reassembly.

The researchers tested the strength of their design by standing two CLT panels measuring 2 meters by 2.8 meters upright in a lateral design setup and pushing on it with 60 kN of force, which far exceeds the lateral forces each panel would usually experience. In testing, the novel wall-to-floor connection system proved fit for reuse following several loading, disassembly and reassembly cycles.

“Reuse means less waste and fewer carbon emissions, so our design’s reusability is an important step forward in circular economy construction methods,” according to Daniela Roscetti, who led the research as part of a master’s thesis under the supervision of Lacroix and Dr Andrea Atkins. Wood Central understands that START plans to refine its design and conduct rigorous testing in the next stage of development. The team is pursuing partnership and funding opportunities.

Is mass timber a no-brainer for mining projects?

Last year, Wood Central revealed that cross-laminated timber was recommended as the construction material for a remote mine in Canada. Arising from a study commissioned by the Thunder Bay Community Economic Development Commission outlines several benefits of using mass timber over traditional construction on remote mine sites.

According to Jamie Taylor, the commission’s CEO, the study presents “a compelling case for mass timber as the cornerstone for mineral development.” The report, supported by the Thunder Bay-based Centre for Research and Innovation in Bio-economy (CRIBE), focused on using mass timber construction systems for the mining establishment infrastructure.

Chris Walton, the CEO of CRIBE, said, “Mass timber construction presents a tremendous opportunity for the mining and resource development sectors to reduce their carbon footprint and project timelines.”

“Substituting steel and concrete for mass timber has been found to reduce emissions by 40%”, with mass timber’s “intrinsic long-term salvage value outperforms conventional lightweight construction.” The study also found that its advantage was reinforced “by its more enduring and resilient structural system, which makes multiple relocations possible without degradation.”

“This study brings forestry and mining together and illustrates the multifaceted benefits of mass timber in the construction of workforce and mining camps,” Mr Taylor said, with timber allowing for “seamless disassembly, which means the systems could be easily repurposed and provide greater flexibility in planning.”