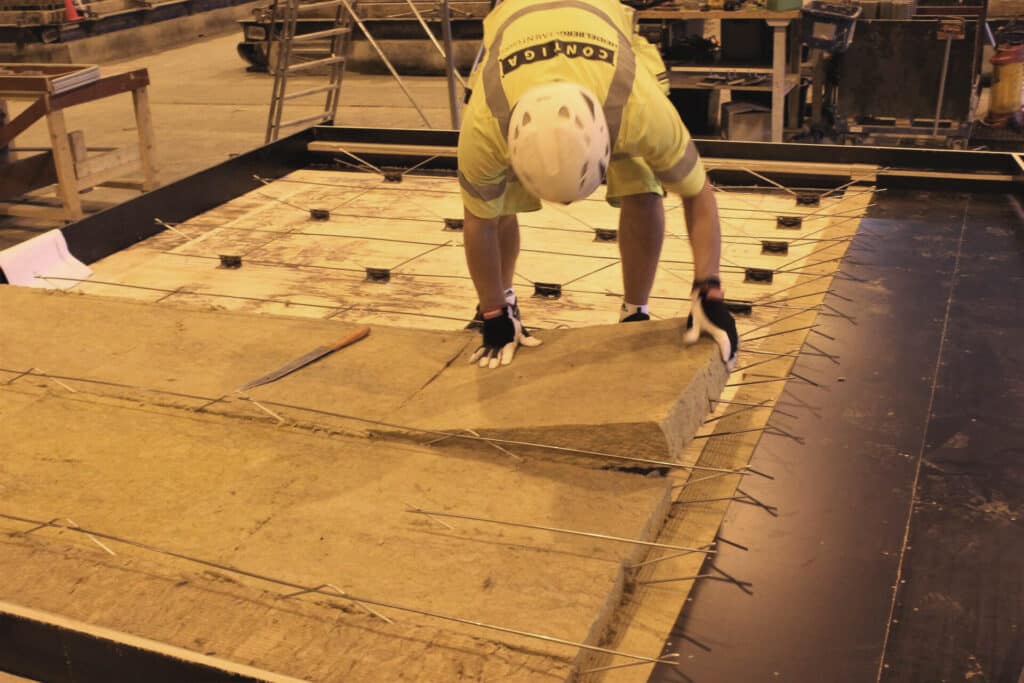

After more than two years of research and development, the first mass timber concrete sandwich, developed by Swedish concrete maker Heidelberg Materials Precast Contiga and Finnish company Metsä Wood, has been successfully tested at Heidelberg’s Norrtälje factory.

It comes after both companies have tested the new product on a building prototype, tested various designs, and assessed how the product reacts to moisture and different forces.

The new product, a wall panel made from layers of concrete, insulation and load-bearing laminated veneer lumber, “capitalises on the benefits of combining wood and concrete in future building structures.”

According to Metsä Wood, the new panels have a climate impact between 30% and 50% lower than a traditional concrete sandwich element, are 60% lighter and are suitable for buildings up to five floors.

In addition, the walls can be made up to 75mm thinner than walls built only with concrete, which adds extra space inside buildings.

“One of the advantages of this hybrid element is that construction contractors do not have to change their way of building with concrete elements but can still lower their carbon dioxide emissions,” said Håkan Arnebrant, Metsä Wood’s business development manager.

The milestone comes after both companies agreed to a commercial partnership last year.

It is the latest example of a hybrid mass timber and concrete product, with global manufacturers looking to develop the next generation of low-carbon materials that are stronger, more durable, and lightweight.

“Around 1 million square meters of concrete wall elements are produced in Finland every year,” Metsä Wood said, adding that replacing all concrete elements with hybrid sandwich elements would reduce CO2 emissions by 30,000 tons yearly, with a further 95,000 tons stored.

According to Heidelberg, the new product is ideal for exterior walls, “providing heightened resistance to weather and wind.” It uses Metsä Wood’s Kerto LVL Q-panel as a load-bearing core panel and an external Heidelberg Materials climate-enhanced concrete panel.

“By developing a hybrid element, we want to see how the different technical properties of wood and concrete can work together to support each other in building structures,” Mr Björman said, adding that the new product is just the beginning of a relationship between the material giants.

The push to embrace mass timber in the concrete mix comes as Heidelberg progresses its commitment to climate-neutral concrete (by 2030), with the company “working on numerous other valuable initiatives to minimise the climate footprint of construction materials,” according to Daniel Eriksson, division manager at Heidelberg Materials Precast Contiga, Norrtälje.

This involves “reducing raw materials throughout the value chain, ensuring the appropriate materials are used in the suitable locations, and developing new products,” with the mass timber-enforced concrete sandwich becoming a valuable addition to the product range.

Research: Hybrid timber systems could be the new reinforced concrete

The partnership comes as global researchers look at hybrid timber, concrete and steel-based systems to meet climate commitments.

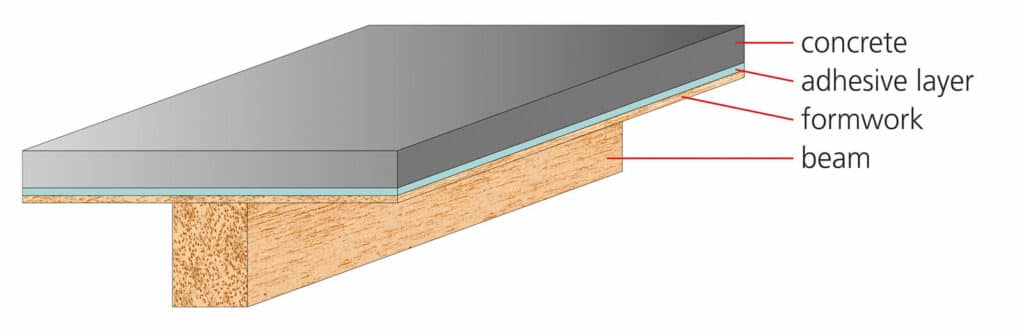

In March 2022, researchers at The Fraunhofer Institute for Wood Research at Wilhelm-Klauditz-Institut set up a research project looking at the long-term value of combining timber and concrete into hybrid building systems.

Scientists worldwide are investigating the amalgamation of timber and concrete and using timber reinforced with carbon fibres or flax in a polymer matrix for increased rigidity.

They have developed a new system for binding timber and concrete without using nails, plates, or nets.

According to Professor Libo Yan, Senior Scientist and Junior Research Group Leader for the project, “By bonding the materials with polyurethane or epoxy resin, we can reduce the weight of the timber hybrids and hasten the manufacturing process by up to 15%.”

As for the concrete sandwich, Heidelberg plans to introduce it into the European market in the coming years and has yet to rule out a global product rollout after that.

Product Facts

- The hybrid wall is a new type of façade element in sandwich construction. It has a concrete outer panel and a load-bearing inner panel made of Kerto wood.

- The hybrid wall has about 40-50% lower climate impact than a traditional concrete sandwich panel.

- In a typical house where the hybrid wall replaces the sandwich wall in the concrete façade, the climate impact of the entire frame can be reduced by 15-25%.

- The hybrid wall weighs about 60% less than a traditional concrete sandwich panel, which means that the transport cost is about 50% lower and reduces the climate impact of the transport by about 50%.