Los Angeles is turning to “factory houses” made of cross-laminated timber systems to construct up-market SuperBungalows as the US’s second-largest city deals with a chronic housing shortage and spiralling building costs.

Set up in 2020 SuperLA® is part of a new wave of start-ups using prefabrication and panelisation to build the next generation of multifamily dwellings. Using cross-laminated timber panels, SuperLA claims that it has cracked the code on low-rise, detached housing. It relies on highly repeatable designs that can be built faster and cheaper than brick, weatherboard, and “stick timber” that dominate traditional bungalows.

That is according to Aaron van Schaik, SuperLA’s founder, an experienced Californian real estate developer who said inefficiencies in residential construction, which subsequently lead to increased costs and bland designs, leaving him both baffled and uninspired:

“Housing is the largest asset class in the world, but the current production process is like if Toyota designed a custom car for every buyer and assembled it in every driveway.”

Aaron van Schaik, SuperLA’s founder on the push to disrupt the residential construction industry.

Instead, SuperLA relies on an operating system known as SuperOS™ that “delivers superior housing in 1/3 the time while maintaining affordability and sustainability.” By reducing time in design, permitting, and construction (from 36-60 months to just 12-18 months), it “saves time and money across every stage of development,” with “savings allowing us to reallocate funds toward building far superior homes.”

SuperBungalows: A new multi-home development in Silver Lake

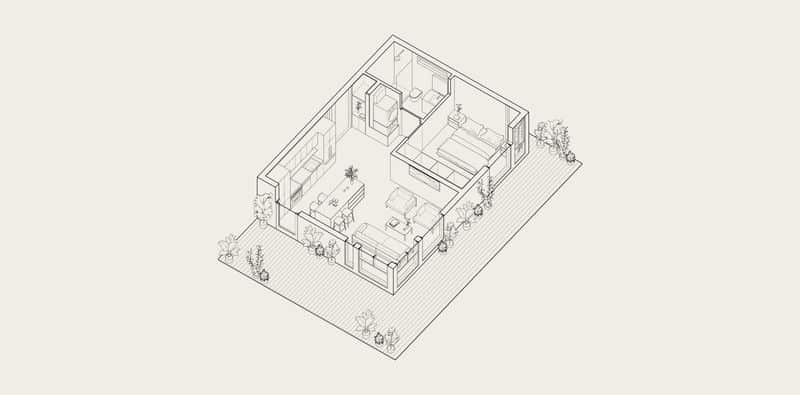

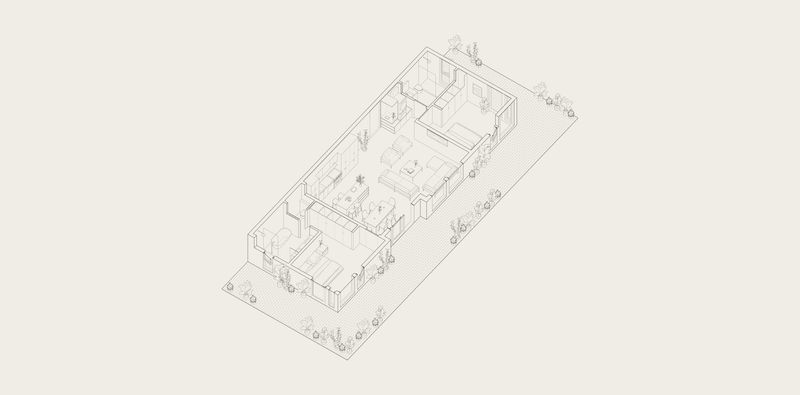

SuperLA’s first housing development is an apartment complex in LA’s Silver Lake neighbourhood called the SuperBungalows. Opened in March, it is Southern California’s first – and certainly not the last – multifamily residential building built from cross-laminated timber.

“The building’s design is a modern take on bungalow court homes that incorporate what makes these designs great. The (nine) homes have no shared walls and feature large private terraces, multiple communal gardens, open-air walkways and stairs, and a ridiculous amount of light and air,” Mr van Schaik told Dwell Magazine last month.

Mr van Schaik also said cross-laminated timber (or CLT) ticks off multiple boxes at the product and process levels: “Reconnecting our occupants with nature is a primary focus,” he said, adding that “over recent years, many studies have demonstrated the benefits of exposed timber within our spaces and its positive impacts on how we feel.”

“CLT also fits our focus on panelizing our builds to optimize construction time. In addition to using prefabricated wall frames, CLT allows us to penalize our floor and roof components, enabling us to fully realize the speed and efficiency of penalizing an entire building.”

Aaron van Schaik on the value of cross-laminated timber systems in driving net-zero housing solitions at scale.

Moving forward, SuperLA is looking at new projects in Los Angeles and across the United States and has not ruled out rolling the solution worldwide in the distant future: “Making this available globally is not out of the question either, but right now, we are hyper-focused on executing the best homes possible starting here in Los Angeles,” Mr van Schaik said.

How much more expensive is building a house in LA?

According to Home Builder Digest, construction costs in California are, on average, 9% higher than the national average home building rates across the US. Within the state, different cities have varying construction estimates:

“If you’re looking to build a home in the state, US News gave a recent list of California’s best places to live, including San Francisco, San Jose, and Los Angeles; it found that a custom home in Los Angeles costs $200 to $400 per square foot, while a more detailed home can start from $450.”

By comparison, costs in San Jose, Menlo Park, Oakland and Brisbane are much lower, varying between $135 and $400 per square foot for a detailed house.

- To learn more about the push to scale up mass timber to capture a higher proportion of the real estate market, visit Wood Central’s special feature.