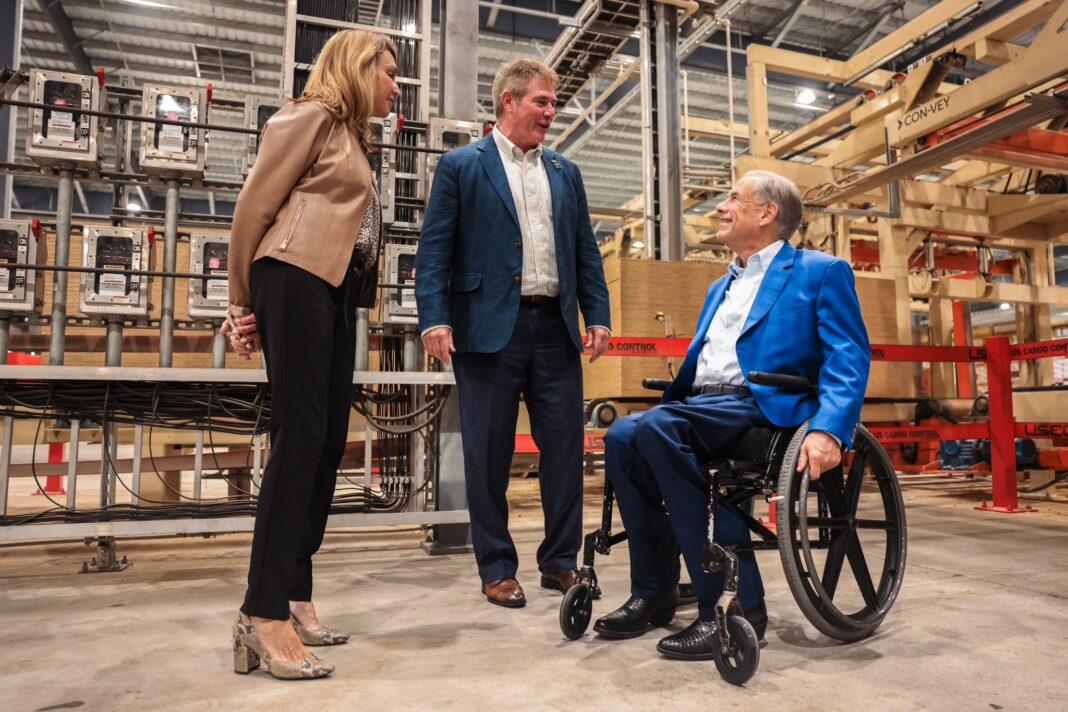

One of the world’s largest timber manufacturing facilities will be located in the Lone Star State, with Greg Abbott, Texas Governor, on-hand to open the first stage of Corrigan OSB’s new US $212m plant, the largest of its type anywhere in North America.

“We are proud that Texas is home to a booming manufacturing sector,” Governor Abbott said. “Corrigan OSB’s expanded manufacturing facility will be the largest OSB facility in North America. It will provide needed, high-quality building materials to Texas’ growing economy. Thanks to our manufacturing sector, ‘Made in Texas’ has never been a bigger brand.”

Corrigan OSB LLC is a wholly owned subsidiary of Martco LLC, a parent company for timber sourcing and manufacturing that uses the RoyOMartin® trademark. The 100-year-old RoyOMartin company is one of two primary timber companies in the region.

The new plant will produce 1.3 billion square feet of OSB every year!

Terry Secrest, Corrigan OSB’s Executive Vice President of Manufacturing and Product Sales, said the new plant will create 300 new jobs for the area: “These are not low-level entry-type jobs that people can create a career with, and they can continue with lifetime employment here, continuing to learn, grow, and excel.”

Texas has a chronic housing shortage, revealing an urgent need for 306,000 more homes. “That’s an issue this plant should help with in the future,” said Mr Secrest. To help in construction, the plant will produce 1.3 billion square feet of product each year.

“To put that in more understandable terms, that will build about 125,000 U.S. homes every single year out of this one plant.”

Terry Secrest, Corrigan OSB’s Executive Vice President of Manufacturing and Product Sales on the importance of the new plant.

Last year, Wood Central revealed that Texas produces enough timber framing studs to visit the moon and return. The numbers are mind-blowing; according to the Texas-based Gilmer Mirror, more than 3.1 billion square feet of structural panels, including OSB, plywood and T1-11 siding, were manufactured in Texas forests.

OSB is Strong Despite America’s Summer of Unwanted Lumber

In August, Wood Central revealed that the world’s largest timber companies were now leaning on OSB to compensate for a very weak lumber market—this comes as engineered wood products are much more resilient in softer timber markets.

Dubbed “perhaps the biggest success story in the entire history of engineered wood,” OSB—a substitute for plywood—uses longer and coarser wood to increase mechanical strength and water resistance. It compresses layers of wood stands with adhesive to ensure consistent density and waterproofing.

Already more popular than plywood in the North American structural panel market—where it now outsells plywood 2-for-1—global adoption is also growing. Earlier this year, Wood Central reported that the Australian OSB market grew by 29% during the COVID boom, and in China, government-backed mills are rapidly expanding production to meet growth in the Global South.

- To learn more about the push by timber companies to invest in OSB production, click here for Wood Central’s special feature.