The age of higher-value forest products is here, with the world’s top forest companies investing in cellulose, cross-laminated timber and biomass to meet a 49% increase in timber consumption.

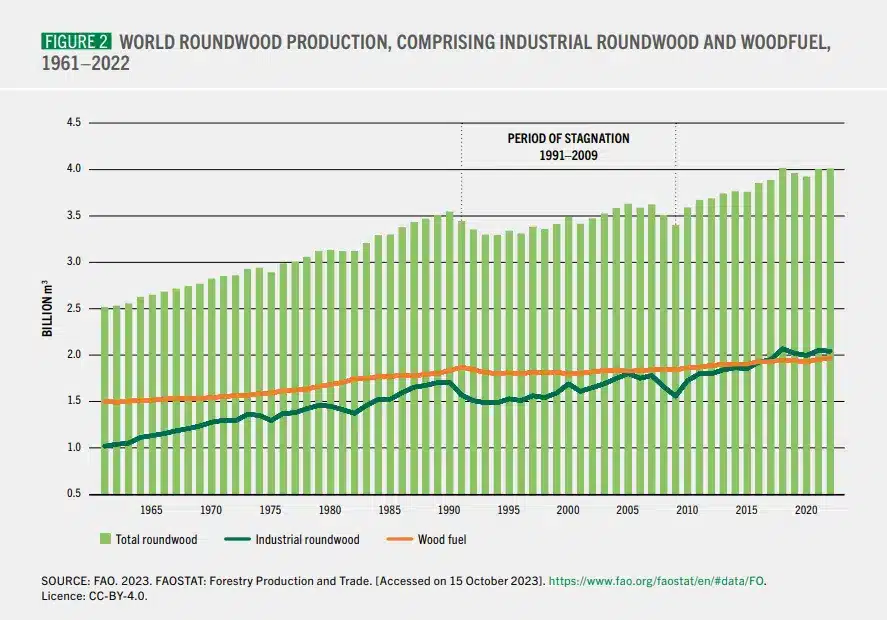

That is according to the FAO’s The State of the World’s Forests 2024: Forest-sector Innovations Towards a More Sustainable Future, which reports that roundwood production might jump by as much as 272 million cubic metres per year by 2050.

“This projection focuses on the demand for wood products,” the FAO said, with “multiple pathways combining increased harvesting and processing efficiency, recycling and planting of forests and trees…(which) can lead to sustainable wood supply in volumes to meet increased demand.”

While “demand for existing products, such as packaging, papers, sawn wood and plywood, is expected to increase, conversely, production of traditionally important wood products is declining,” the FAO said, including “newsprint, printing and writing paper.”

For example, the FAO estimates that, in line with current trends, the decline in graphics paper production would reduce roundwood demand by 133 million cubic metres over the next five years alone.

The next generation of wood products is everywhere!

In May, Wood Central spoke to Duncan Mayes, one of the FAO report’s contributors to the Innovation in the Forestry Sector section, who said that global forest companies are now investing heavily in wood-use efficiency.

The trick is to use lignin, cellulose and even hemicellulose to enhance the value of wood, said Mr Mayes, the founder and principal of Helsinki-based Lignutech Oy, also the author of the FAO’s case example 17, looking at the opportunities to utilise mass timber construction in both upgrading and building within earth prone areas.

According to Mr Mayes – who will be a keynote speaker at Timber Construct on August 12 and 13, cellulose and (lignin) are being used as alternatives or added to carbon-intensive materials to “green up.”

Mr Mayes, who advises MDF Recovery Ltd, UK, behind the world’s first MDF recycling process enabling the transition to the circular economy, is working with companies across Europe and Worldwide to develop the next generation of wood-based products.

“Industry is now integrating cellulose from wood into cement, used in concrete structures,” Mr Mayes said.

“It enables the speed of curing of the concrete structure to be increased and even 3D printed while enhancing the strength of the concrete. Similar functionality has been found with lignin. It may also reduce the amount of corrosion-prone steel needed to reinforce the concrete.”

A holistic approach to how we use wood

According to Mr Mayes, the construction industry’s view of forest products must shift. “Having a holistic view of products and the broader industry ecosystem is important,” he said, adding that “there is an entire body of work evolving on this,” with the industry now using new technologies to manufacture products on demand.

“In Finland and Sweden, for example, there has always been a tradition of multi-sector integration, with the big forest companies having pulp mills, paper mills, board mills, sawmills and most recently mass timber plants combined in an industrial ecosystem,” he said.

“These are highly integrated companies,” Mr Mayes said, adding that the companies “look at the synergies between the different processing, equipment, machinery, and raw materials… they’re highly efficient operations, there is no spare chips, bark or sawdust, it’s all used.”

Then, there is improved wood efficiency; thanks to modern technologies, the FAO reported that “15% more finished products can be produced in 2022 compared with 1961 for the same volume of roundwood.”

“If this trend of increasing efficiency continues for the next couple of decades, it will be possible to produce the same volume of product as today in 2040 using 116 million cubic metres of industrial roundwood.”

“If this trend of increasing efficiency continues for the next couple of decades, it will be possible to produce the same volume of product as today in 2040 using 116 million cubic metres of industrial roundwood.”

- To learn more about the FAO and its projection for the State of the World’s Forests, visit Wood Central’s special feature.