Swedish firm Modvion is disrupting the wind power market with new wooden wind turbine towers cutting emissions by up to 90% compared to steel alternatives.

Funded by the EU through the EIC Fund, the towers harness powerful winds; offer cost-effective energy production, and act as carbon sinks, reducing total turbine emissions by up to 30%.

The idea of wood-based wind turbines has taken hold across Europe, with firms on the verge of scaling up prototypes and early versions.

In Germany, Voodin Blade Technology is working with Stora Enso to create wooden turbine blades. A 20m blade for a 0.5-megawatt turbine is currently being manufactured, and plans are underway for an 80m version suitable for a turbine with a capacity of up to 6 megawatts – the size utilised in commercial farms.

New partnership with Metsä Wood to produce LVL wind turbines

In a media statement released Tuesday (Australian time) Modvion has partnered with Metsä Wood to supply laminated veneer lumber (LVL) for its wooden towers. After 25 to 30 years, the fully circular turbines can be disassembled and reused after decommissioning.

Based in Espoo, Finland, Metsä Wood (formerly ‘Finnforest’) is part of the Metsä Group which covers the whole wood value chain.

Pär Hallgren, Modvion’s Head of Procurement, stressed the significance of the partnership paving the way for Modvion to become one of the largest LVL buyers in the European market.

“Metsä Wood is an important partner in our journey to become a leading supplier of the next generation of sustainable wind turbine towers, which will also make us potentially one of the largest buyers of LVL,” Hallgren said.

LVL is essential with the strength-to-weight ratio resulting in lighter towers with less need for expensive reinforcements. Previously, Modvion entered into a similar partnership with Stora Enso.

“Kerto LVL enables high material efficiency thus making it ideal for sustainable construction,” says Henrik Söderström, Sales and Marketing at Metsä Wood.

“Alongside the technical benefits of LVL, it also enables radical reductions in emissions,” he said.

According to a report by Herald Scotland, a typical 110-meter steel wind turbine tower emits approximately 1,250 tonnes of CO2. In contrast, a wooden tower only releases about 125 tonnes of CO2 and has the added benefit of storing carbon.

These wooden towers are constructed using adhesive instead of bolts, which reduces the necessity for frequent inspections.

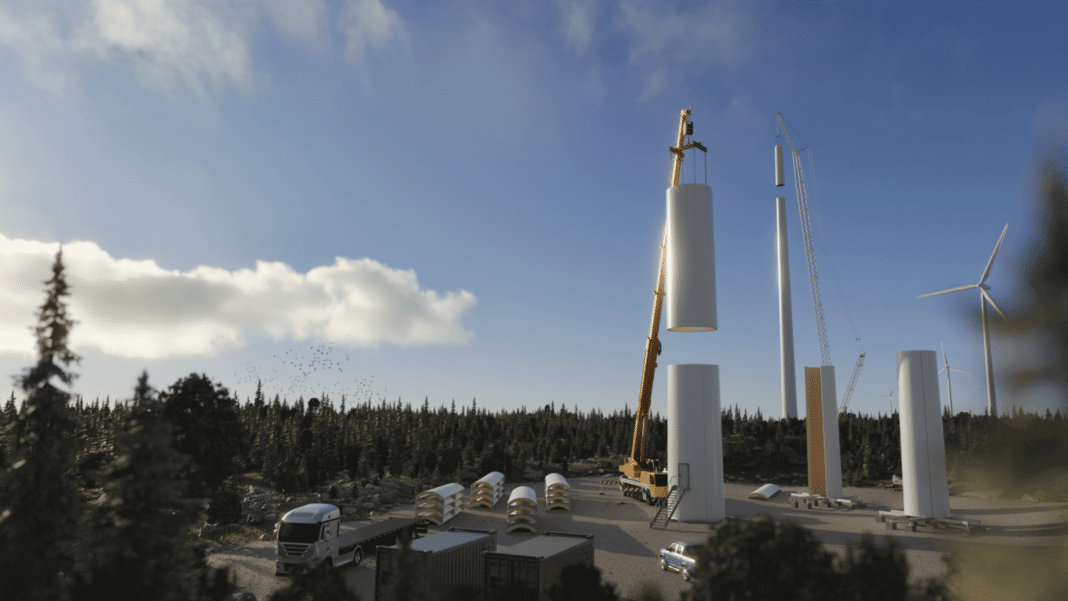

The first 30-metre wooden tower was erected by Modvion near Gothenburg in 2020, with plans to construct a full-scale 150-meter commercial tower later this year.

Renewable Energy Systems has signed a letter of intent for 200 LVL turbines

Last month, UK energy firm Renewable Energy Systems (RES) signed a letter of intent to use around 20 towers per year from 2026 to 2036. RES has developed or constructed 21 wind farms in Scotland with a total capacity of 597 MW.

At the time of the announcement, it was reported that wooden towers could help address challenges in steel manufacturing while meeting the growing demand for wind turbines.

Scotland, with its abundant Sitka spruce, is well-positioned to supply raw materials into the turbine manufacturing. These wooden towers are designed to withstand harsh weather conditions and are coated with weather protection to prevent water damage.

“We currently use Scandinavian spruce but any soft wood works, including Sitka spruce. Scotland is very much possible for supplying raw material for wooden towers,” according to a Modvion spokesperson.

As more LVL turbines are constructed, confidence in the technology is expected to grow.

Dr. Dan Ridley-Ellis, Head of the Centre for Wood Science and Technology at Edinburgh Napier University, explained that while LVL has been utilised for 30 years, it is relatively new for large-scale construction. As more wooden turbines are built, trust in the technology should increase.

“This is not an entirely new concept – people have built wind turbines and components from wood before,” Dr Ridley-Ellis said.

“This specific type of engineered wood, LVL, is somewhat like plywood, but instead of the layers being at 90˚ to each other, different layers all go in the same direction.”

However, there is some uncertainty among engineers regarding the effectiveness of LVL in the construction of wind turbines, he added.

“We don’t have extensive experience in building wind turbines, regardless of the material used. There is a lot of general uncertainty because they are a relatively new kind of structure.

“The more that are built and the more people witness them functioning, the more they will start to trust the technology.

“You wouldn’t want to construct numerous turbines in remote areas only to discover that you need to carry out unexpected maintenance regularly.”