The world’s first multi-storey structure made from recycled concrete, steel, and self-shaped cross-laminated timber (CLT) has been erected in Southern Germany.

Designed by the University of Stuttgart’s Integrative Computational Design and Construction for Architecture Cluster of Excellence (IntCDC), the new Wangen Tower, which opened earlier this month, was assembled in just three days!

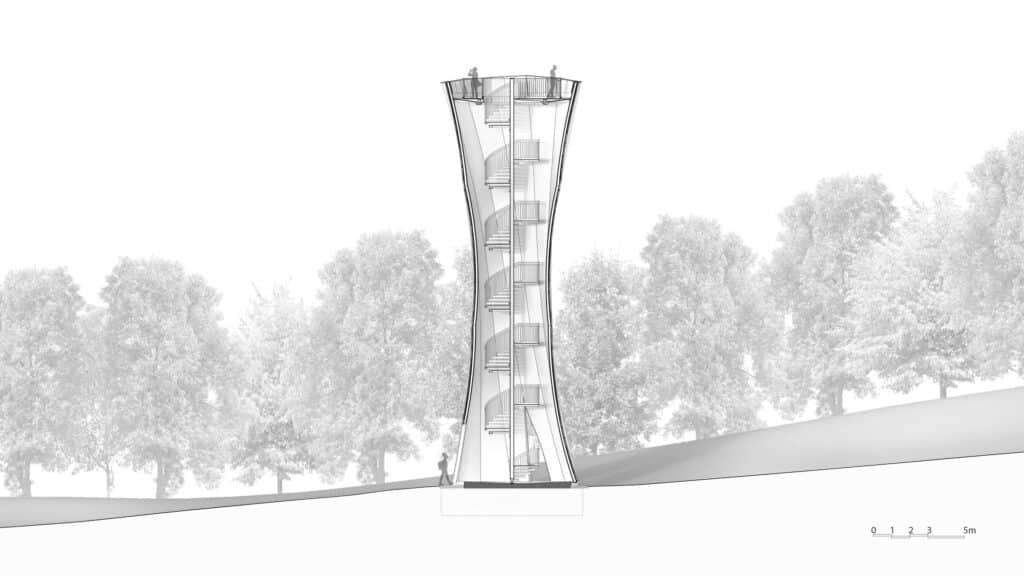

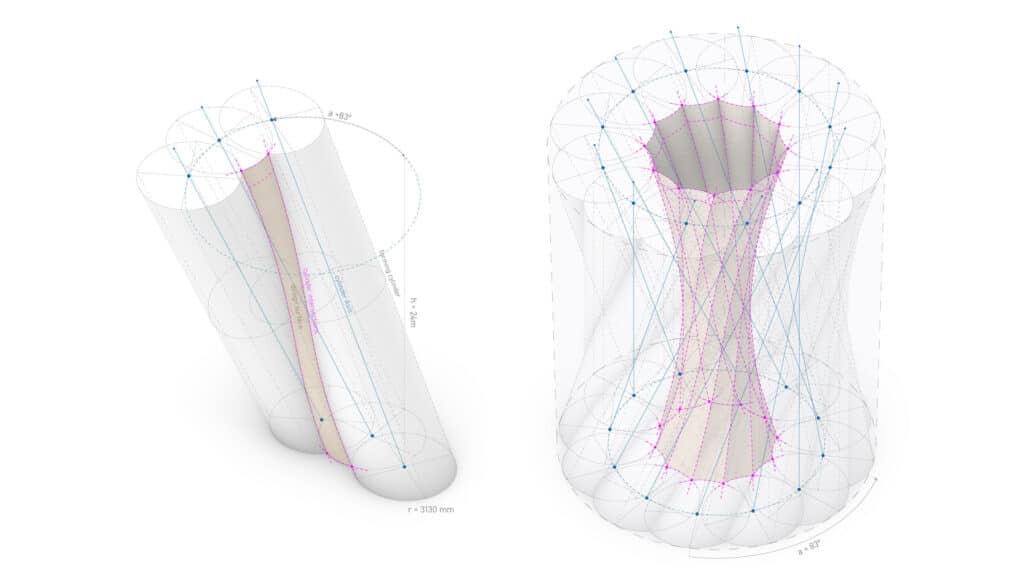

Standing 23 meters tall, the Wangen Tower comprises twelve long structural segments manufactured from three different CLT elements. Each element is precision-machined using 5-axis CNC technology, then connected through a newly developed mono-material lap joint. According to IntCDC, this joint “transmits forces in all directions, creating continuous CLT, all while maintaining constant cross-sectional dimensions.”

The tower’s helix-shaped spiral and the curvature of its CLT surfaces form a surface-active timber structure capable of withstanding horizontal wind loads. IntCDC explains that the curvature adds stiffness to the timber, similar to a corrugated sheet.

Moreover, the central spine of the staircase supports vertical loads and elegantly highlights the precise load distribution among the structural components by tapering at the base.

Professor Jan Knippers, head of the Institute of Building Structures and Structural Design, noted that “the innovation in timber construction is enabled by an integrative approach to scientific research, computational design, digital fabrication, and expert craftsmanship.”

He added that the tower’s curved timber components are based on a self-shaping manufacturing process influenced by wood’s moisture-induced shrinking.

Wangen Tower was designed, certified, and constructed over the course of a year. The University of Stuttgart’s IntCDC used 3D computer modelling to create the spire. The self-shaped components are made from flat panels consisting of a 30-millimeter-thick ‘active’ layer and a 10-millimeter-thin ‘restrictive’ layer.

After lamination, the panels undergo controlled kiln-drying, during which the active layer shrinks perpendicularly to the fibre direction, shaping the panels into their curved form. Three bilayer plates and a thin locking layer are laminated to form a curved 130-millimeter-thin CLT panel.

To enhance efficiency, the structural segments were pre-assembled into pairs, minimising on-site construction time to just three days. Steel connectors and most of the facade’s 168 individually crafted larch panels were pre-mounted in the factory.

The components were then installed on-site on a shallow foundation made from recycled concrete with CO2-reduced cement. Finally, the spiral staircase and viewing platform were inserted from above to complete the structure.

“The distinctive expression of the tower’s unique timber structure showcases the design possibilities in renewable, locally sourced, and resource-effective timber architecture,” said Professor Achim Menges, Director of Cluster of Excellence IntCDC.

Wangen Tower details

- Height: approx. 23 meters (75 feet)

- Footprint: 50 square meters (538 square feet)

- Viewing tower diameter: 5.6 meters (18 feet)

- Foundation: recycled concrete with CO2-reduced cement

- Timber structure: twelve curved CLT panels with 130-millimeter thickness and a total surface area of 360 square meters (3,875 square feet)

- Staircase: hot-dip galvanized steel spiral staircase with 113 steps

- Viewing platform: hot-dip galvanized steel structure with glass panels

Project partners

- Cluster of Excellence IntCDC — Integrative Computational Design and Construction for Architecture, University of Stuttgart

- Institute for Computational Design and Construction (ICD): Prof. Achim Menges, Martin Alvarez, Monika Göbel, Laura Kiesewetter, David Stieler, and Dr. Dylan Wood, with the support of Gonzalo Muñoz Guerrero, Alina Turean, and Aaron Wagner

- Institute of Building Structures and Structural Design (ITKE): Professor Dr. Jan Knippers and Gregor Neubauer

- Blumer-Lehmann AG: Katharina Lehmann, David Riggenbach, and Jan Gantenbein

- Biedenkapp Stahlbau GmbH: Markus Reischmann and Frank Jahr

- Stadt Wangen im Allgäu — Landesgartenschau Wangen im Allgäu 2024 GmbH