An Australian academic is working hard to create a new sustainable building material composite of timber and steel.

Griffth University PhD candidate Shelley Karkoodi is working with Brisbane-based Geoinventions, a specialist geotechnical engineering consultancy, to apply her knowledge “in practice.”

Ms Karkoodi, who last month published her first paper in the Construction and Building Materials Journal, said, “Australia has excellent sources of timber.”

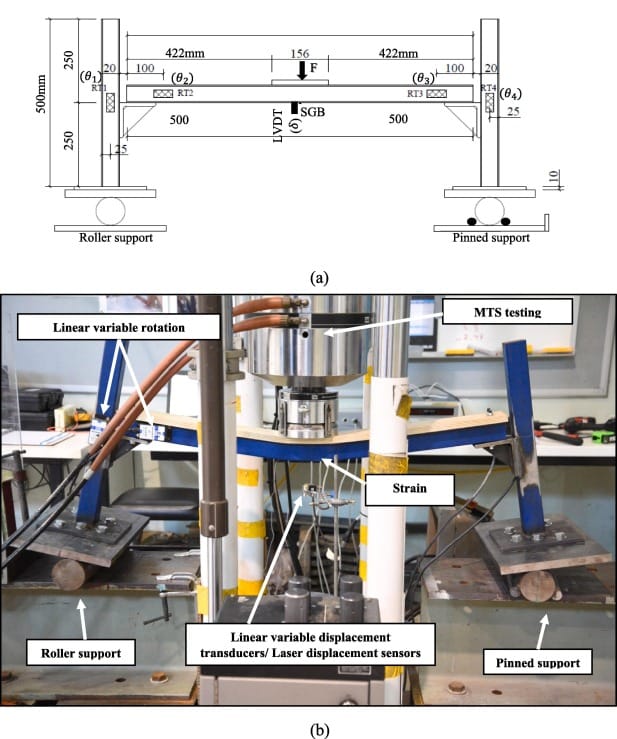

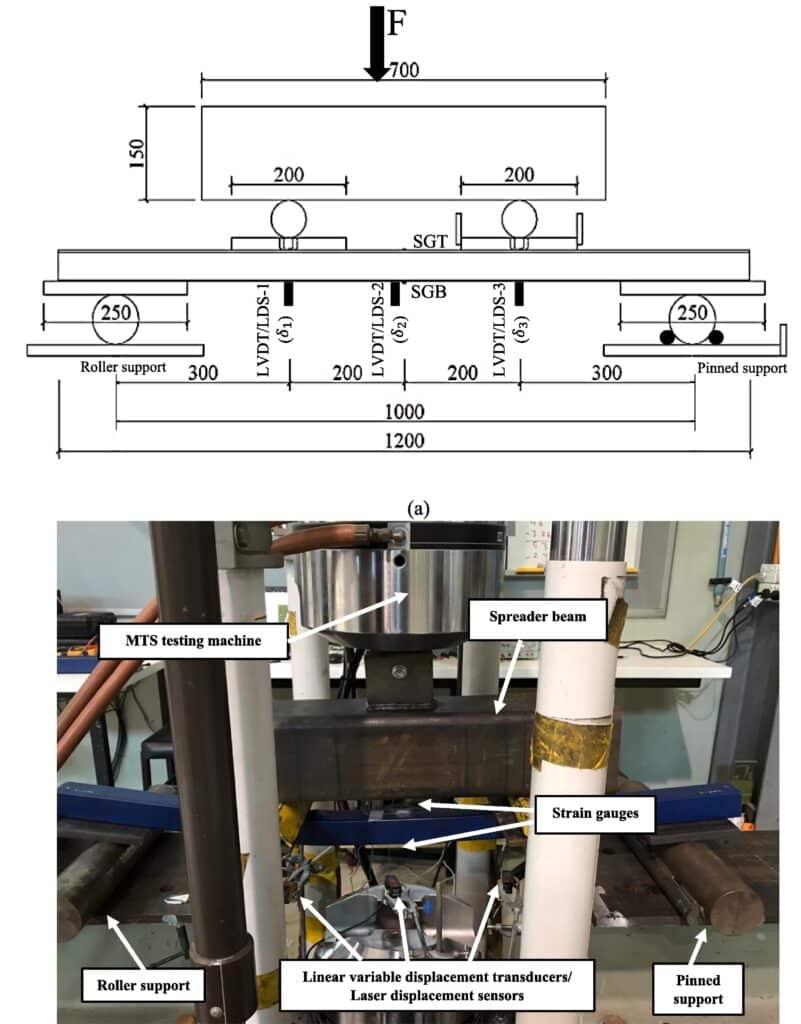

The paper, funded by Forest and Wood Products Australia through the National University Wood Challenge, “represents a comprehensive exploration, both numerically and experimentally, of a steel tubular system infused with fibres for construction applications.”

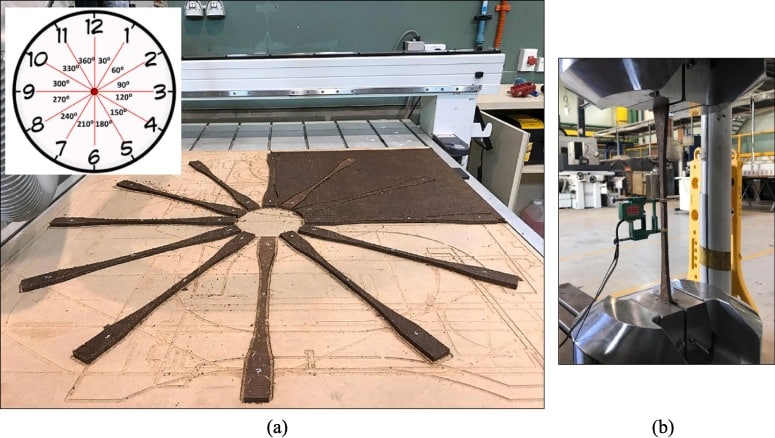

It looked at testing fibre-filled steel tubular (FFST) posts and beams created by inserting dried wood fibre products into cold-formed steel square hollow sections.

According to Ms Karkoodi, the hybrid product can produce building structures with less environmental impact and carbon footprint “but also bring lighter, taller and long-spanning solutions.”

“Moreover, efficient technologies can be used to rework or recycle wood products, such as fibres, into hybrid modules to assist the growing trend towards a circular economy.”

The result of the research, as well as ease of assembly, “suggest that the proposed FFST frames can be upscaled and potentially be used in residential dwellings or similar low-rise applications.”

Before starting her PhD at Griffith University, Ms Karkoodi studied Mechanical Engineering at the Amirkabir University of Technology and the Tarbiat Modares University in Tehran, Iran.

Her masters’ thesis analysed “The Behaviour of Wooden Composites Reinforced with Nanoparticles under Impact Loadings.”

Supervised by Professor Hassan Karampu, her research revolves around structural analysis, computer simulation and trying to find design rules for the new material.

More recently, she started a block internship with Geoinventions to help her gain transferable skills used in future projects.

“It’s an Australian company trying to develop a new product,” she said.

“So we’re doing structural analysis and computer simulations of a composite material that can be used as pavements, which is quite similar to what I am doing in my PhD.”

Hybrid materials provide “the best of both worlds”

As reported in April, developers are increasingly looking to hybrid construction materials – combining mass timber, concrete and steel construction to maximise efficiencies and “get the best of all worlds.”

Recent advancements in adhesive and manufacturing technology have made it possible to fabricate extensive yet lightweight engineering wood panels (EWP) with enhanced mechanical properties, dimensional stability and a strength-over-density ratio comparable to steel.

In 2019, researchers from the University of NSW published research in the Journal of Construction Steel Research, which looked at the behaviour of bolt and screw shear connectors in steel-timber composite (STC) beams.

Led by Associate Professor Hamid Valipour and Laureate Professor Mark Bradford, it demonstrated, for the first time, the superior structural performance of innovative steel-timber systems over conventional steel-concrete systems through a series of bending tests on beams and connectors.

“Building with steel-timber composites means there is no waiting, and upward construction can be seamlessly ongoing,” the research team said.

“Alongside no wait is less weight. This reduces cranage and injury risk. Steel-timber composites increase the efficiency of moving, lifting and placing panels.”

Therefore, steel-timber composite can significantly increase the speed of construction and reduce the noise and pollution associated with construction activities.