Forestry is amongst the industries most impacted by the push towards Artificial Intelligence (AI) and Automation.

In our latest series on AI, Wood Central is exploring the impact of ‘software learning’ on the modular construction industry.

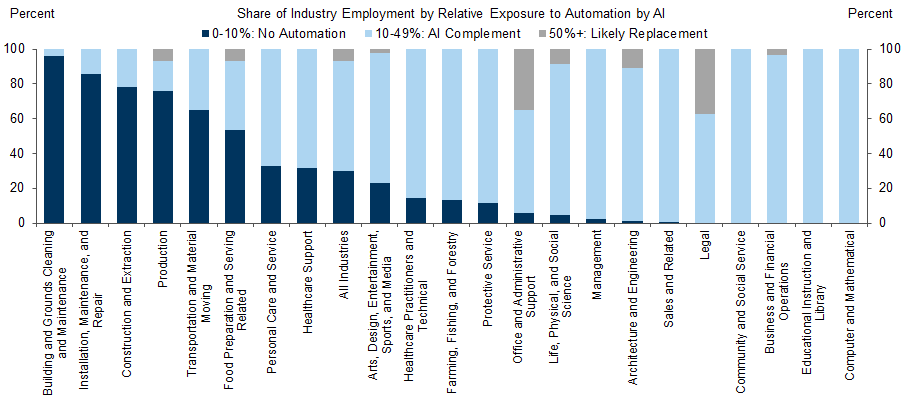

According to a report published by Goldman Sachs, the production and construction industry have about 20% exposure to AI replacement – including 3D printing and robotics.

AI will change the construction industry ‘forever’

As reported by Construct Connect, AI is already disrupting the North American construction industry.

John McMullen of the US’s Modular Building Institute (MBI) says AI is changing the construction industry “forever,” he said. “But don’t all technologies do that?”

Mr McMullen said AI’s potential in modular is virtually unlimited.

“Building plans can be optimised for the capabilities of specific manufacturers.”

“The quality control and plan approval processes could radically change,” he said.

“Efficiencies could be found and implemented to reduce building times and material waste.”

Architects and building designers are using AI software to design buildings

Last month, Wood Central reported that architects and building designers are now using ‘Midjoinery’ software to design mixed-use mass timber buildings.

The real question, Mr McMullen said, is how modular builders and designers implement AI to deliver modular’s benefits best.

“I think it’ll be a gradual process, but, eventually, AI will be a valuable tool for the industry.”

The CEO of the Building Design Association of Australia (BDAA) revealed that building designers also use AI and automation in Australian projects.

Chris Knierim is the CEO of the national peak body for the building design community and revealed that “AI is already having an impact on the design industry.”

According to Mr Knierim, it can assist in generating design options, analysing data, and optimising building performance.

“It can quickly process vast amounts of information, helping designers make informed decisions and explore innovative solutions.”

“AI-driven simulations can evaluate designs’ environmental impact and energy efficiency, leading to more sustainable and eco-friendly buildings.”

In the US, MBI executive director Tom Hardiman mentioned that the exact impact of AI on modular construction is still being determined

“We’ll have a better idea in a few months once we start receiving requests from people to speak at the next World of Modular, the MBI’s annual conference, in 2024.”

Craig Mitchell, founder and principal of Blackbox Offsite Solutions Ltd, said AI’s most significant opportunity in modular is on the design side.

“It shows a lot of promise for creating iterations of modular design that can adapt to different site characteristics and constraints.”

Puyan Zadeh, a research associate in the civil engineering department at the University of British Columbia, says AI and intelligent automation significantly benefit the different stages of offsite construction.

For example, Ms Zadeh said AI could be used at the manufacturing stage for design and quality control and to implement robotics.

The power of robotics

AI can also improve logistics. It can forecast deliveries, anticipate transportation problems and optimise how prefab components are loaded and arranged on trucks.

And when it’s time for prefabs to be installed, AI tools can optimise the process by determining the best number of workers, amount and type of equipment, and by organising work crews.

In June 2023, Wood Central reported that modular housing company BloKlok uses labour-less robots to manufacture modular housing in Sweden.

BoKlok has used the technology to deliver 14,000 affordable houses in Sweden, Finland, Norway, and the UK.

According to Clarissa Brandt, Strategic Relations Manager at Timber Queensland, who attended the facility, robotics could answer labour shortages that have long plagued the construction industry.

“The benefits are many, including reducing workplace health and safety risks,” Ms Brandt said.

“In a time-motion study, one of their clients indicated a robot saved 22,000 tonnes of lifting for one person in one year.

AI can greatly enhance BIM technology

According to Ms Zadeh, Building Information Modeling (BIM) is ripe for immediate disruption by AI.

“If we consider BIM as Building Information Management, however, the potential applications for AI is even greater.”

“BIM in this context requires extensive collaboration and coordination among different disciplines, which AI can significantly enhance.”

AI can act as a virtual assistant, improve communication among team members and help make project scheduling more flexible and adaptive.

Dorian Tung, Manager of Building Systems at FPInnovations said AI could be a boon to modular in the future.

Still, smart robots with sensors can assemble standardised prefab components with everything the correct size.

The future of construction lies in combining robotics, AI and other technologies such as automation, computation, software, sensing and networking, said Helen Goodland, Head of Research and Innovation at Scius Advisory, a Vancouver consulting firm.

“Advanced manufacturing, as it is known, is already being done in many other industries.”

“More construction companies need to get on board now too”.

“One local company that has already started is Intelligent City.”

Oliver Lang, co-founder and CEO of Intelligent City Inc., said his company takes what he calls a product-based approach to creating housing solutions that are faster and more efficient to build, as well as carbon-neutral.

“We have developed a fully integrated housing technology platform called Platform for Life,” Mr Lang said.

“It integrates design engineering, AI, parametric software, robotics, and mass timber building systems.”

“The result is a scalable platform with scalable, repeatable, adaptable building solutions.”

“It is a fundamental departure from today’s custom-made, cost-prohibitive broken incumbent building solutions.”