Why are walls always straight? Why does it cost so much to build them? And why do construction projects often run late?

Construction has always been a conservative industry …doing things as they have always done.

But a new wave of innovation is coming that will change how buildings look, how they are made, and who wins in the new era of construction.

The age of the zero-labour Robot

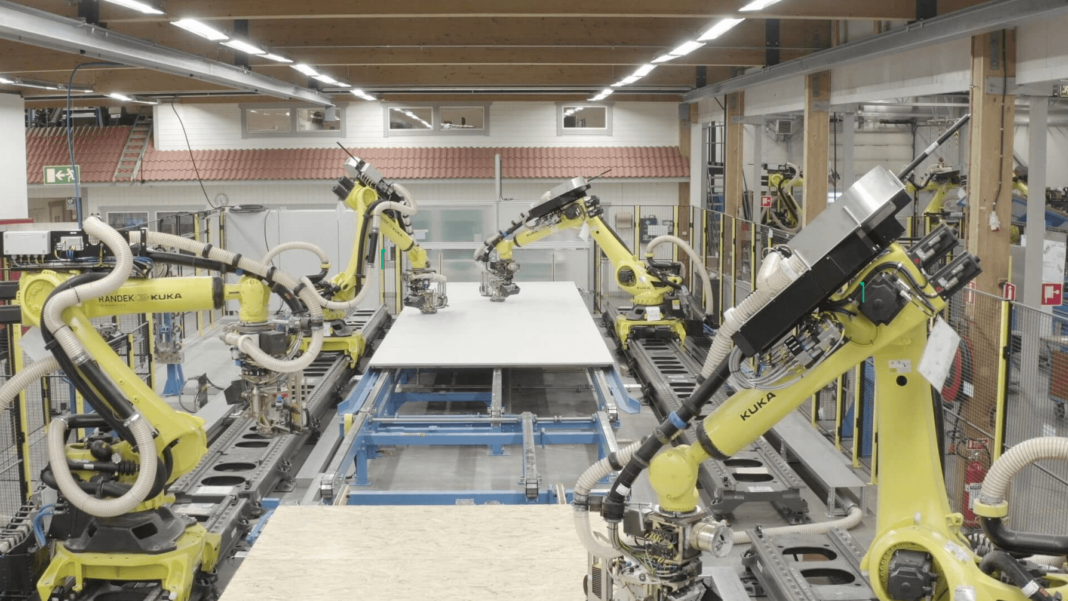

Australian delegates on the Wood Solutions and Timber Development Association study to Europe this week saw first-hand how robots are manufactured at the Randek AB facility in Snickaregatan, Sweden.

Led by CEO Christian Olafsson, the delegation enjoyed an extensive behind-the-scenes tour of the facilities and a look at robots in action.

The fully-automated Randek Zero Labor Robotic can automate the total prefabrication process for house construction.

The system is used by BoKlok, a joint venture between IKEA and Swedish development company Skanska. BoKlok has delivered 14,000 affordable houses in Sweden, Finland, Norway\, and the UK.

Timbertruss, Australia’s largest component prefabrication company, uses the technology to improve accuracy, speed, and safety in production.

Supplying roof trusses, wall frames, posi-struts, and cassette floor panels, the technology has been instrumental in pushing the company’s national expansion.

According to delegate Clarissa Brandt, Strategic Relations Manager at Timber Queensland, robotics could answer labour shortages that have long plagued the construction industry.

“The benefits are many, including reducing workplace health and safety risks,” Clarissa says.

“In a time-motion study, one of their clients indicated a robot saved 22,000 tonnes of lifting for one person in one year.

Randek is a small company with less than 100 employees, but it has had an enormous impact on the construction industry by developing technology that automates offsite construction.

Through its technology, CAD drawings can be mass-produced in a factory setting and only require assembly onsite.

International expansion of Randek technology

In December 2021, Randek AB joined forces with SCM, one of the world’s largest machinery suppliers, in a new global cooperation aiming to become a one-stop supplier for the complete timber construction process.

Under the partnership, SCM will distribute the widest range of robotic solutions for beams, walls, timber frames, X-lam/CLT panels machines.

The new partnership expands and strengthens the range of technological solutions both players provide.

Robotics has spurred global interest in modular housing

According to Forbes, the latest take on modular housing is volumetric modular manufacturing (VMM) … creating many residential units at an offsite facility.

Many houses are shipped directly from the factory up to 95%, with windows, flooring, painted drywall, plumbing fixtures, lighting fixtures, doors, and kitchen cabinets with countertops.

Moving forward, construction companies are now improving automated assembly lines by incorporating robotics, such as the Randek Zero Labor Robotic System, and artificial intelligence into supply chains.

This allows construction companies to combine sub-assemblies into larger and more complete units with workers free from repetitive and dangerous tasks.

Technicians and engineers program and maintain specialised equipment to ensure that sub-assemblies consistently comply with high-quality standards and tolerances.