As revellers celebrated the end of the year, Central Japan was rocked by a 7.5-magnitude earthquake, triggering the country’s first tsunami warning since the infamous 2011 Tōhoku ‘nuclear’ event.

The quake, Japan’s most potent for several decades, has already toppled buildings, causing fire and knocking out critical infrastructure in the Noto Peninsula just as families celebrated New Year’s Day.

Since January 1st, more than 1,200 aftershocks have also blighted the region, with rescuers hampered by blocked roads and poor weather to clear the wreckage – and aid 3,500 still stuck in isolated communities.

To date, the death toll from the earthquake has passed 200 – with authorities confirming that another 100 are still unaccounted for.

However, despite its casualties, Japan has fared far better than comparable examples, including Turkey’s 7.8-magnitude earthquake last February, which claimed 50,000 lives, with its success attributed to the resilience of its buildings in the face of structural collapse.

The reason for this?

For more than 100 years, Japan has been at the cutting edge of seismic architecture and structural engineering, changing building codes to mitigate risks from 1,500 earthquakes every year. As a result, Japan has adjusted its standards for structural engineering, turning past disasters into hard lessons for a safer future.

These changes began in 1923 when a 7.9-magnitude earthquake flattened Yokohama, killing more than 140,000 people and toppling hundreds of thousands of structures – with many of Japan’s ancient buildings, made from wood, not equipped to handle frequent quakes.

This tragedy allowed Japan to introduce the world’s strongest and most advanced seismic standards to its building codes, now known as the Building Standards Act, bolstering new and existing timber and concrete-based construction, particularly in heavily urbanised areas like downtown Tokyo.

Japan, which is among the largest consumers of timber in constriction worldwide, has now specified that “all buildings must not collapse during an earthquake of any force, despite the damage they sustain” – including detached housing, which, from 1981, must be built for “sustainable human life” during an earthquake.

Timber Engineering Research looks at Seismic Protection Technologies

As Japan now looks to taller mass timber buildings to drive decarbonisation, seismic protection technologies (SPTs) have emerged as a hotspot in timber engineering research.

This includes seismic dampers and base isolation, described as the “Cadillac of performance options when you protect buildings in high seismic locations,” according to California-based structural engineer Krista Looza, who remarked on the resilience of Japan’s timber buildings under heavy shock.

“They have almost three times as many earthquakes as we see here in California,” he said. “And California is considered a region of high seismicity. So you can imagine, in Japan, they are very prepared and aware of the hazards they live around.”

According to Architecture Digest, seismic dampers are placed between the columns and beams of each building floor and employ piston heads in cylinders of silicone oil to transfer vibrations to the liquid rather than the structure during an earthquake.

Base isolations come in many forms and at many price points, from rubber pads installed at the building’s foundation to act as tremor absorbers to decoupling an entire structure from its foundation and setting it atop a flexible pad so that when the ground shakes, the architecture remains intact and stable.

“The most economical option to protect a structure from cracks and collapse is fortification, making walls, columns, and beams thicker to better handle stress during a natural disaster.”

When a building is under construction, architects can specify materials like precast concrete walls, which help absorb lateral loads, or steel moment frames to build support directly into the structure.

“Reinforced concrete and structural steel bracing are contemporary industry standards that were long thought to be better options than wood; however, engineered products like cross-laminated timber have recently been proven lateral force resistant by the US Forest Service, which has led to a building code change for approval of CLT structures in seismic areas.”

Quake Test on the World’s Tallest Full-Scale Timber Building

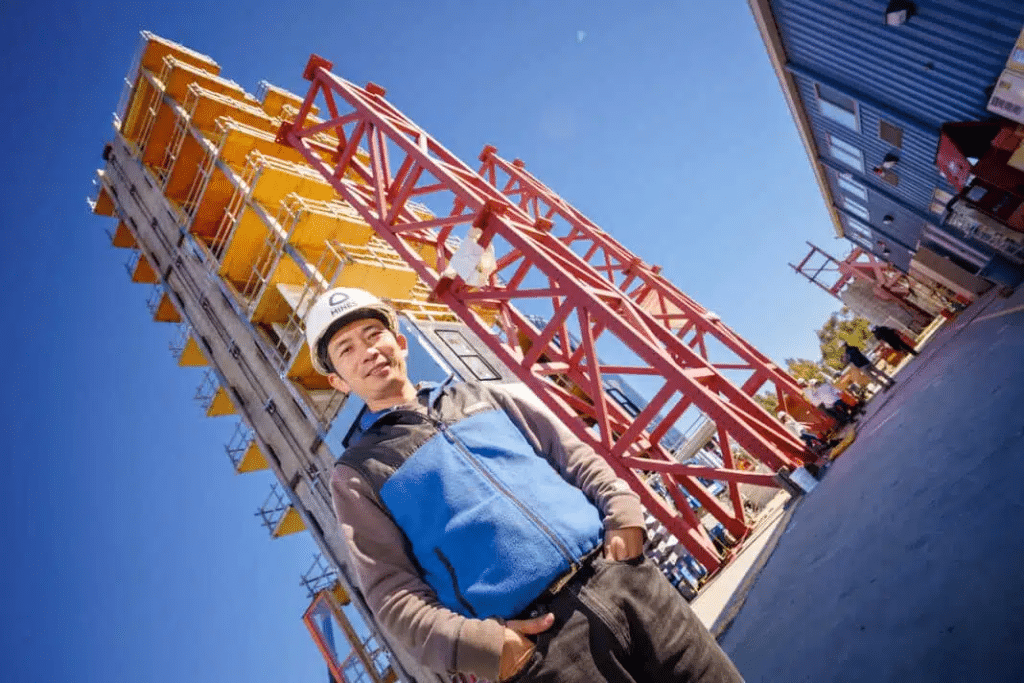

In June, Wood Central reported that researchers in California, also subject to high seismic activity, were using “the shake table” to test a 10-storey cross-laminated timber building at the University of California San Diego.

Previously reported by Science Blog, the experiment, known as the TallWood Project, is the tallest full-scale building ever to undergo testing on an earthquake simulator or shake table.

The shake table can recreate earthquake movements of various magnitudes on the Richter scale, ranging from 4 to 8, by mimicking seismic activity from past earthquakes, including the Northridge earthquake that hit Los Angeles in 1994.

“The combination of the largest payload capacity in the world, an outdoor setting, and the newly added six-degrees-of-freedom shaking capability make the UC San Diego shake table a powerful and unique facility,” said Professor Joel Conte, principal of the Department of Structural Engineering at the UC San Diego Jacobs School of Engineering.

“It’s the only place where the TallWood Project tests could happen,” Conte said.

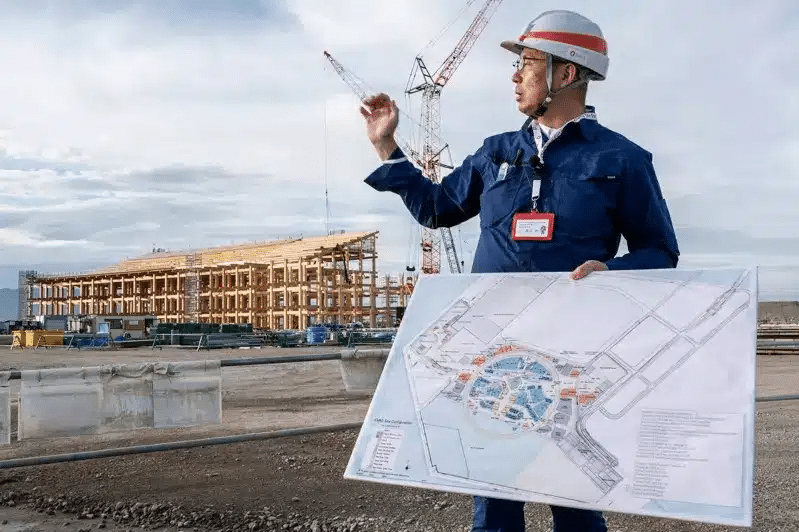

Mass timber buildings are gaining popularity as greener and faster alternatives to concrete and steel structures – including the 11-storey Port Plus building, which rose in Tokyo last year.

With new building codes updated to permit more high-rise mass-timber buildings, many questions exist about how such buildings would fare in earthquakes.

“Mass timber is part of a massive trend in architecture and construction, but the seismic performance of tall buildings made with these new systems is not as well-understood as other existing building systems,” said Shiling Pei, principal investigator and associate professor of civil and environmental engineering at Colorado School of Mines.

Meanwhile, in Japan, engineers say preparedness is the best way to combat an earthquake’s potentially deadly effects. After every event, Japanese scientists instrument buildings to find where they have gone structurally wrong. This knowledge helps ensure that every subsequent tremor will be less disastrous than the last.