Thousands of ‘public buildings’ across the US, including schools, colleges, office buildings and military installations, could be built from ‘innovative wood products’ after a new bill, which would see the establishment of the Mass Timber Federal Buildings Act, was read before Congress.

The Act—which has bipartisan support—is an industry “game-changer”, according to Tyler Fresers, Vice President of Sales for Frerers Lumber, behind Portland’s Airport massive timber roof, set to rise later this year, who said “six mills across the Pacific Northwest have closed in the last four months alone.”

Introduced by Senators Jeff Merkley (a Democrat) and James Risch (a Republican), the bill is the latest push to promote an industry expected to grow between 25 and 40-fold over the next 30 years. It will prioritise locally grown and manufactured timber over imports, which are currently 10-15% cheaper than US-made equivalents. The bill comes amid a race to use mass timber and hybrid timber construction systems in public buildings worldwide.

In announcing the bill, Senator Merkley said, “Mass timber from right here in Oregon is already a key piece of the puzzle to solving our nation’s affordable housing crisis and tackling climate chaos.” Before adding, the Act “will ensure we build federal projects using mass timber products, helping the nation’s biggest challenges while creating good-paying jobs in Oregon and across the United States.”

Senator Risch added, “Idaho’s forest products industry supports rural economies, reduces wildfire risk, and produces high-quality building materials.” The new Act “opens opportunities for Idaho’s timber industry and ensures our government offices are built with the best of the best.”

Should it pass, the Act will mandate a preference in federal building contracts for mass timber products. According to a joint statement from the two senators, “This will give mass timber companies the ability to compete for federal construction, renovation, or acquisition of public buildings and military construction.”

The bill creates a two-tier contracting preference—the first applies to mass timber coming from state, federal, private, and Tribal forestlands, whilst the second applies to mass timber products sourced from restoration practices, fire mitigation projects and underserved forest owners. In addition, there will be a requirement to conduct building lifecycle assessments, which are the data to learn more about carbon sequestration in mass timber buildings.

“It’s abundantly clear that mass timber and wood construction are right-now climate solutions supporting and growing our rural communities,” according to Jackson Morrill, President and CEO of the American Wood Council, who said the language will “ensure that these emerging markets are supporting by American manufacturing and sustainably sourced American wood products.”

According to Travis Joseph, President of the American Forest Resource Council, the bill is essential to honouring the US pledge at COP28, which will see 17 of the world’s largest timber-consuming countries vow to use more timber in public buildings. “The new Act recognises the benefits of active forest management and the climate benefits of using wood products grown, harvested and manufactured right here in America.”

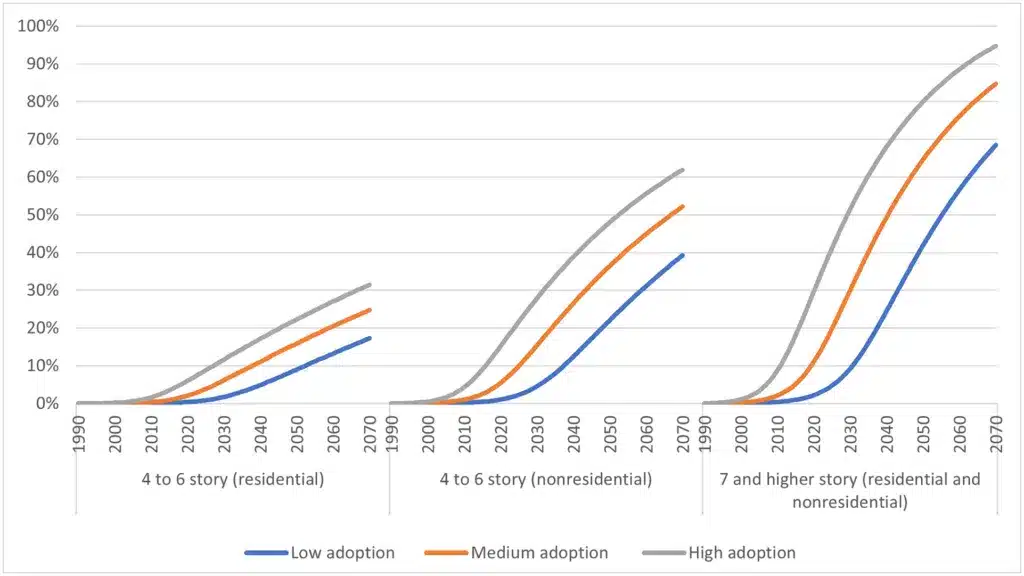

Last month, Wood Central reported that “favourable public policies and the removal of barriers to market adoption” could see mass timber grow from 0.362 million cubic metres or 0.4% of the American softwood industry to between 452 million and 750 million cubic metres, with “the greatest adoption rates projected for the seven-stories and higher,” fuelled by a surge in new buildings in the South (43%), followed by the West (23%), the Midwest (21%) and the Northeast (13%).

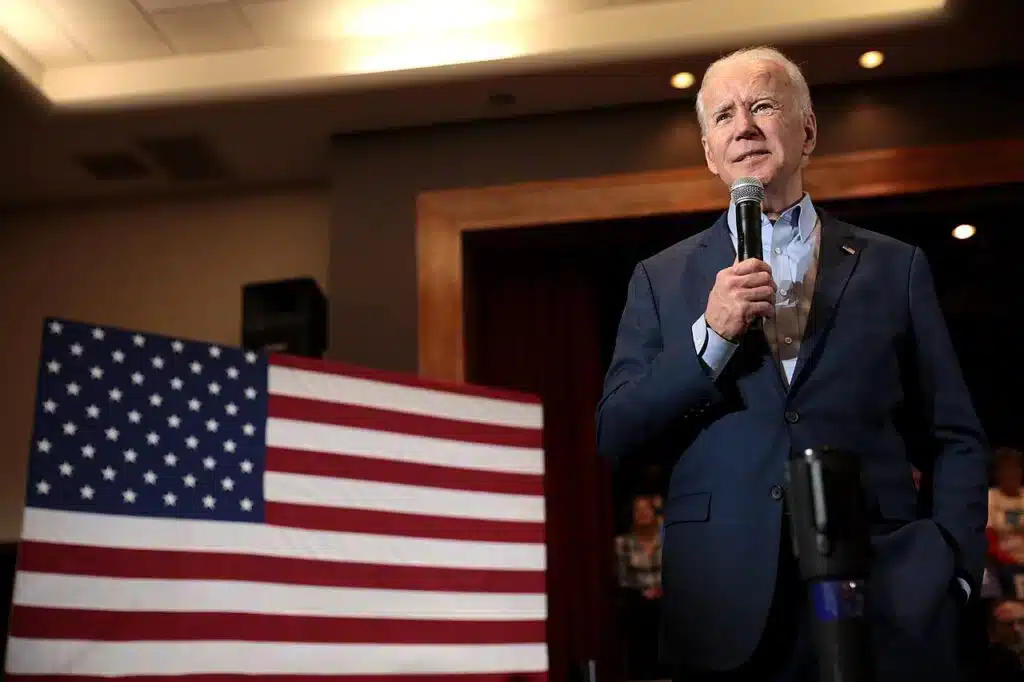

To date, the Pacific West has been the epicentre of the timber switch, with President Biden establishing a “Mass Timber Hub” in Oregon – which has seen the University of Oregan, Oregan State University, and the TallWood Design Institute join to form the Oregan Mass Timber Coalition – with the coalition pushing to ramp up production to create economies of scale and push down the price of domestic mass timber.

For Ian MacDonald, the director of the TallWood Design Institute, prioritising US timber production is crucial. “If we just incentivise using more mass timber generally, there’s a danger of building a market for European competitors, who currently have a price advantage.”

“There’s kind of a race to this around the world right now,” he said, adding, “I think this is excellent timing. We need to get to the point of global competitiveness.”

The US Army is already using mass timber, with engineers working with material scientists to create new cross-laminated products, known as “advanced cross-laminated timber,” to be used in housing projects, counterterrorism, and force protection projects.

Last year, Wood Central reported that the US Corp of Engineers was testing new mass timber products made from highly accessible (and economical) Western Hemlock, reinforcing timbers with biomass from the aviation industry to scale up timber production for future projects.