A US university is turning to a new mass timber construction system known as wave layered timber (WLT) to solve the growing housing crisis gripping the country and the world.

The current housing crisis is shaping to be one of the defining policy areas in the 2024 US election – with a shortfall of up to 5 million dwellings just the tip of the iceberg,

Last year, Wood Central reported that a Detroit-based start-up was using robotics and 3D printing to build 7-day houses out of cross-laminated timber.

Now, students at the University of Arkansas – one of the regions worst hit by the crisis – are using prefabricated construction to create affordable houses for workers earning just $16 to $18 an hour.

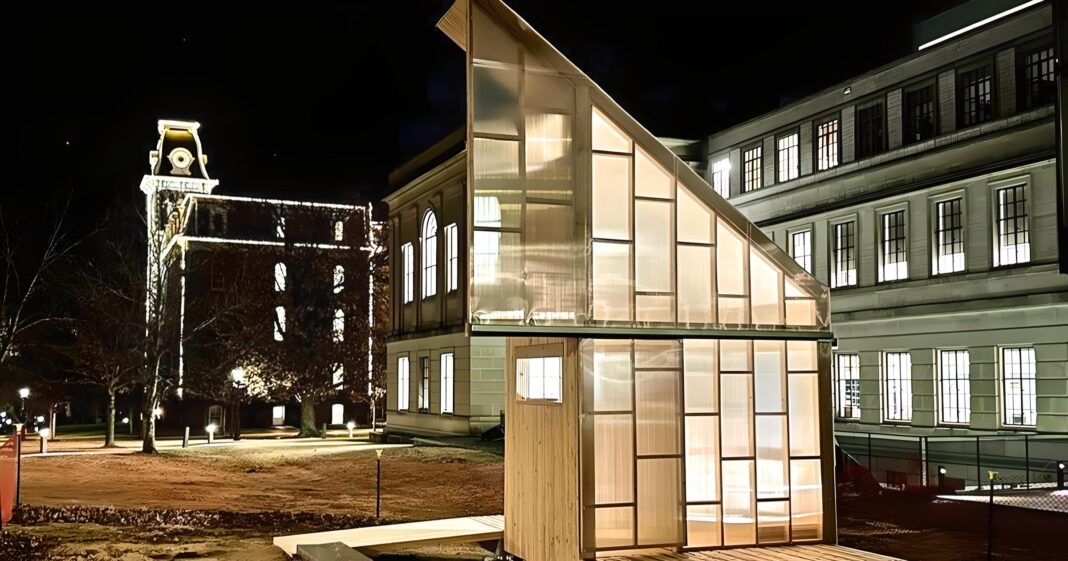

The prototype, billed Workforce 16, is 152 square metres in size, expanding to at least 210 square metres to allow for growing income or family size. If successful, the university plans to develop permanent modular houses to sell in the US real estate market.

According to John Folan, Professor and head of the Fay Jones School of Architecture and Design, the prototype “is all about addressing a social need.”

“The idea is to give people a start at wealth building through home ownership. Residents can expand into the shell space provided with original construction as their needs and resources allow.”

Significantly, the use of WLT – a glue-free timber system, utilises the strength of the wave shape to lock together self-tightening components. Developed by Finnish-based Aalto Haitek, it is an addictive, free and natural wave-layered timber used to build houses, bridges or even skyscrapers.

Since 2018, the technology has already been used in hundreds of projects worldwide, with the Finnish suppliers struggling to lift capacity to meet demand.

“The capacity of the new production facility is nowhere near enough; the demand is just fierce,” according to Aalto Haitek’s founder and Director of Development, Janne Honkala.

“Orders are coming in from all over the world, with enquiries about up to thirty thousand houses. There is no way we can make such quantities”, Mr Honkala said, who, over the past four years, has had extensive requests for the WLT to be involved in a range of projects, including the Notre Dame de Paris restoration.

The push to embrace new and innovative solutions comes as President Biden announced in October the development of the Pacific Northwest Mass Timber Tech Hub, which the president said will “use advanced material science to develop low-carbon housing solutions.”

An initiative of the TallWood Design Insitute follows a US $41 million commitment, also by the Biden Administration in 2022, to expand the use of mass timber in housing as part of the Oregon Mass Timber Coalition.

That saw the Port of Portland explore turning Terminal 2 at the PDX Airport under construction into a manufacturing hub for mass timber construction.

“We will be able to put more supply of manufactured housing — up to 2,000 houses per year — into the market,” said Keith Leavitt, the Chief Trade and Equitable Development Officer for the Port of Portland.

Under the plan, a private operator will run a factory on the airport site, selling mass timber prefabricated homes at a price that low and middle-income customers can afford.

According to the American Enterprise Institute, a conservative think-tank, housing supply will be one of the definitive battlegrounds that will shape a presumptive Biden v Trump presidential re-run from 2020.

It claims that the lack of affordable housing, fuelled by material and labour shortages, has hindered the job market and held back economic growth by making it harder for workers to access good-paying jobs.