A world-renowned architect has called for greater investment in wood processing as the country grapples with a shortage of materials for housing.

In his inaugural lecture at the University of Auckland, Dr Anthony Hōete – a past NZ Institute of Architecture winner – called for greater investment in the country’s wood supply.

“Processing more timber onshore will impact housing supply while creating new jobs to support regional communities and would reinforce our commitment to a net-zero carbon future,” said Dr Hōete, the Architecture and Urban Planning Professor at the University of Auckland.

Dr Hōete’s design and research have played a key role in advancing New Zealand and Māori architecture worldwide.

In 2002, Dr Hōete established WHAT_Architecture and has been awarded 40 national and international awards.

He is registered as an architect in Aotearoa, New Zealand, Australia, The Netherlands and the United Kingdom, where he was awarded the most prestigious prize in NZ and UK architecture.

According to Dr Hōete, Aotearoa, New Zealand, enjoys one of the world’s most extensive and productive man-forests but falls short in adding value to the resource.

“These days, the problem isn’t that we have a shortage of logs, Dr Hōete says. “It’s that we’re not turning them into lumber.”

“Lumber is a log with the added value from primary processing, while logs are a raw product with no added value.”

“By March 2022, 61% of our logs (22 million m³) left Aotearoa, New Zealand. We are now the world’s biggest log exporter, supplying 20% of the global market. Eighty per cent of our logs are bound for China, where state intervention subsidises transport.”

China’s slowdown creates a big problem for NZ exporters

Wood Central has extensively reported on New Zealand’s reliance on China as an export market.

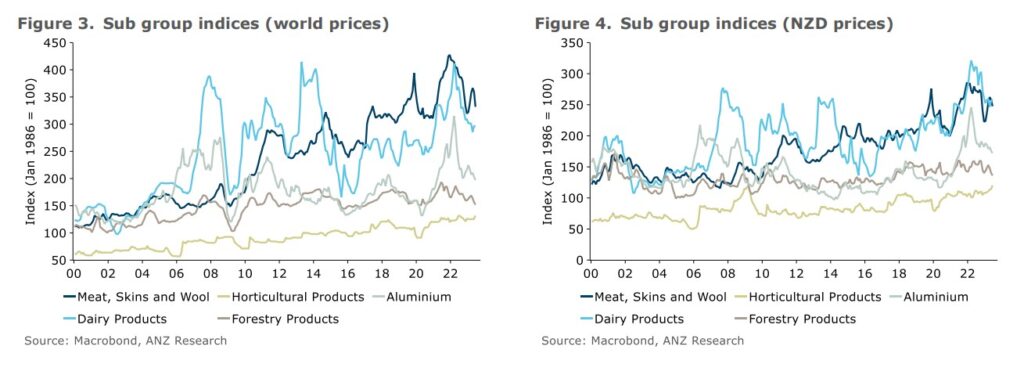

This week, the ANZ Commodity Price Index published data for June 2023 pointing to a 21% reduction in log prices over the past 12 months owing to the Chinese construction slowdown.

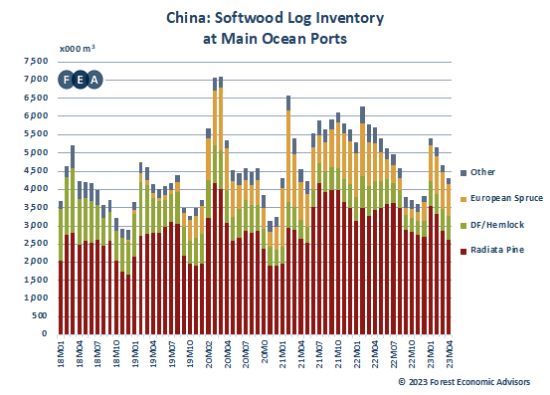

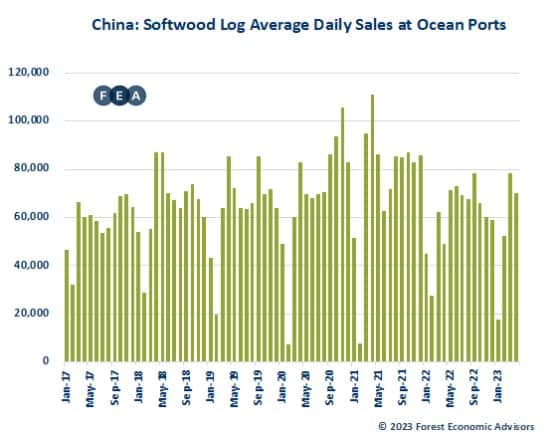

In April, data from Chinese ports identified that inventories were 8% lower than in past months, while a recent PF Olsen report identified that Chinese importers were late on payments.

According to data supplied by the World Resources Institute, New Zealand’s market share of China’s total log imports was 58%, followed by Germany (14%), Poland (5%), the US (5%), Canada (4%), and Japan (4%).

In recent months, the industry has called for NZ to broaden its export markets to include India, the European Union and Australia.

Still, Dr Hōete has called for the government to boost support for local manufacturing.

“Why can China offer higher prices for New Zealand logs than local companies? In two words: wood processing.”

“The Chinese wood industry consists of 100,000 individual companies, most of them small and medium-sized enterprises (SMEs).”

“China adds value to New Zealand logs by processing the wood into plywood, which is then turned into furniture and exported back around the Pacific.”

Dr Hōete taught at TU Delft and The Bartlett UCL – among the top two architecture schools in the world and has called on the government to support local processing through investment in innovation.

“Since 2000, forest harvest volume in New Zealand has doubled from 17 million to 36 million m³, while processing has remained constant at 13 million m³,” he adds.

“Value-added wood products comprise just 15 per cent of our forestry export volumes yet generate over 40 per cent of export revenue.”

NZ Industry Transformation is a step in the right direction

He points to the ‘Forestry and Wood Processing Industry Transformation‘ launched by the Te Uru Rākau (NZ Forest Service) in 2022 – which has allocated NZD 57 million for industry capacity building.

“It plans to create a higher value and resilient forestry and wood processing sector to underpin our low emissions future,” he said.

But instead of selling grain Dr Hōete argues NZ needs to be baking and earning bread.

“Aotearoa, New Zealand has a small population, and we need to think more strategically so that economic growth is driven by productivity rather than hours worked.”

“Innovation is critical to lifting productivity. Small Advanced Economies (SAEs) like Singapore and Sweden invest ten times more than New Zealand in innovation to overcome the barriers of size and distance.”

“In 2021, the NZ Productivity Commission found that “Māori authorities were demonstrating higher rates of innovation”.”

“The design course on papakāinga, which I teach at the School of Architecture and Planning, strives for innovation through models such as the collectively owned, build-to-rent, flood-plain elevated, 30-bedroom house.”

Local Mass Timber market is an opportunity

In 2016, Dr Hōete founded the London-based, Game of Architecture, specialising in build-to-rent affordable housing made from cross-laminated timber.

“Housing doesn’t need to be a smorgasbord of materiality as it currently often is,” he said. “It could be timber-centric instead.”

“We could build not with ‘sticks’ (stud work) but with solid timber panels fabricated off-site using digital computer numerically controlled (CNC) techniques.”

“At WHAT_architecture, we developed, designed and constructed a build-to-rent papakāinga block of houses in London that was manufactured from cross-laminated timber panels,” he said.

In 2021, the project won the NZ Institute of Architects International Award.

There are 64 CLT manufacturers in the Northern Hemisphere but few in the Southern Hemisphere.

“Supplying the South-East Asian and Latin American markets is an economic opportunity waiting to be grasped by Government investment and alignment with the wood processing sector.”

So how can NZ boost its local capacity?

According to Dr Hōete, the answer lies in partnering with forest-owning iwi.

“Why not use the money to partner with forest-owning iwi, such as Ngāti Awa, and build a wood processing factory near Kawerau or Whakatāne? The forests there have excellent rail connections to the nation’s largest port, Tauranga.”

The answer lies in state-owned enterprises.

“Historically, the Government played a crucial role in establishing and growing the forestry and wood processing sector.”

“As all wood processing in New Zealand today is privately owned, why not have a state-owned enterprise?”

“Processing more timber onshore will impact the housing supply while creating jobs to support regional communities and would reinforce our commitment to a net-zero carbon future.”